Demonstration project

Multi-SOFC

Climate-friendly energy supply at the hospital in Erkelenz

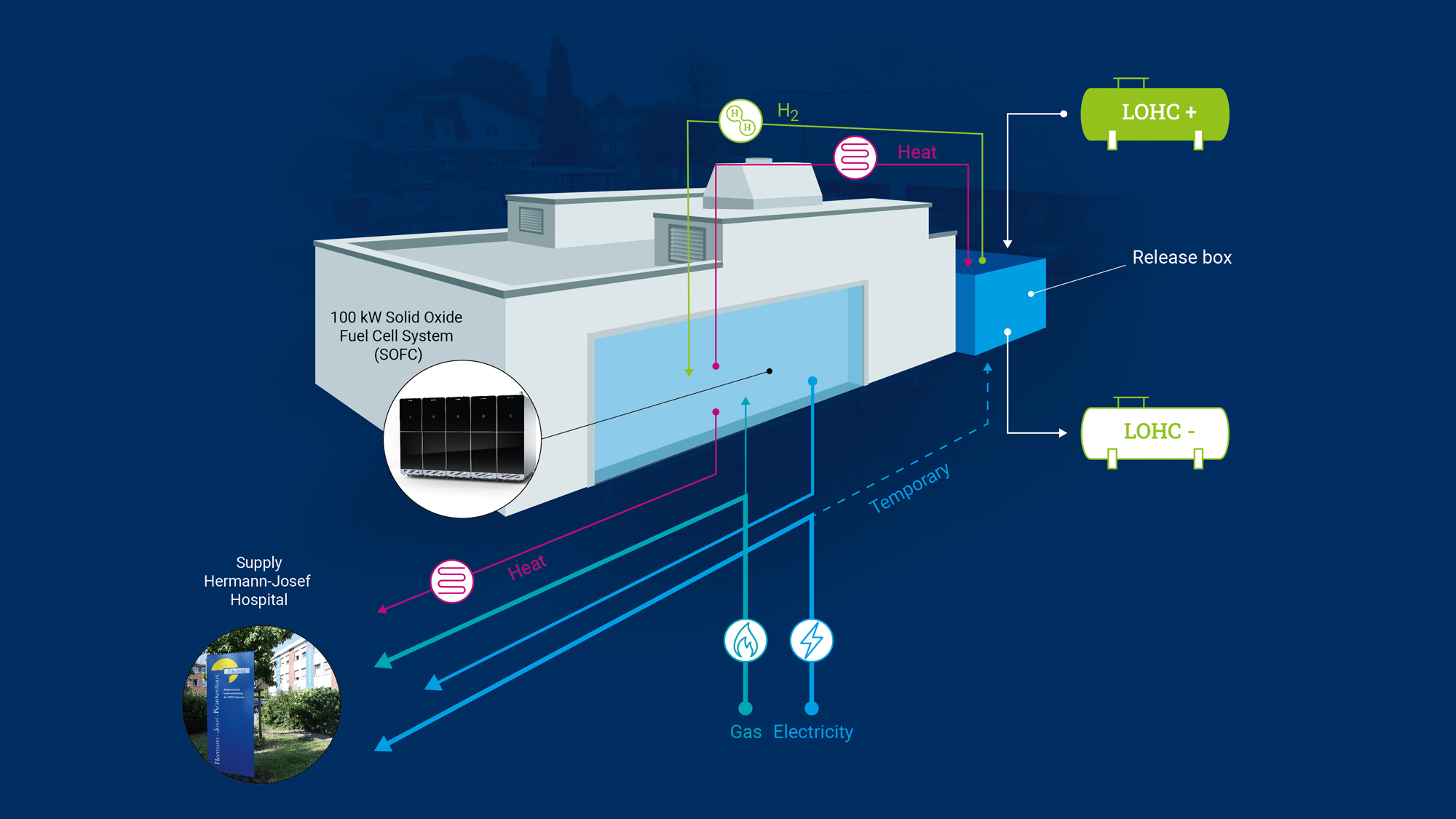

A more climate-friendly energy supply is the goal that the partners want to demonstrate by the end of the project. This will create a flagship project in Erkelenz that can develop far-reaching appeal. Robert Bosch GmbH and Hydrogenious LOHC NRW GmbH are demonstrating the coupling of new hydrogen technologies on an economically relevant scale for the first time at the Herman-Josef Hospital. The aim is to make the hospital’s energy supply more climate-friendly and cost-effective. The Federal Ministry of Education and Research (BMBF) is funding the project with 23.6 million euros.

Die Robert Bosch GmbH, die Hydrogenious LOHC NRW GmbH, das Hermann-Josef-Krankenhaus Erkelenz und das Helmholtz-Wasserstoffcluster wollen zeigen, dass die neue Kombination der beiden Wasserstofftechnologien 20 Prozent des Strom- und Wärmebedarfs des Erkelenzer Krankenhauses decken kann. Dies ist eine relevante Größenordnung, die eine Skalierung der Technologie für größere Bedarfe und andere Anwendungen ermöglicht.

Management of the project

“We are convinced that the technologies shown in our Multi-SOFC demonstration project can attract a great deal of interest. We are continuously optimising the new system during the project and will have a data set at the end that the project partners can use as a basis for scaling up the combined system for industrial applications.”

Dr. Michael Alders, senior project engineer at HC-H2. Photo: ©Forschungszentrum Jülich/Limbach

What happens here, technical details

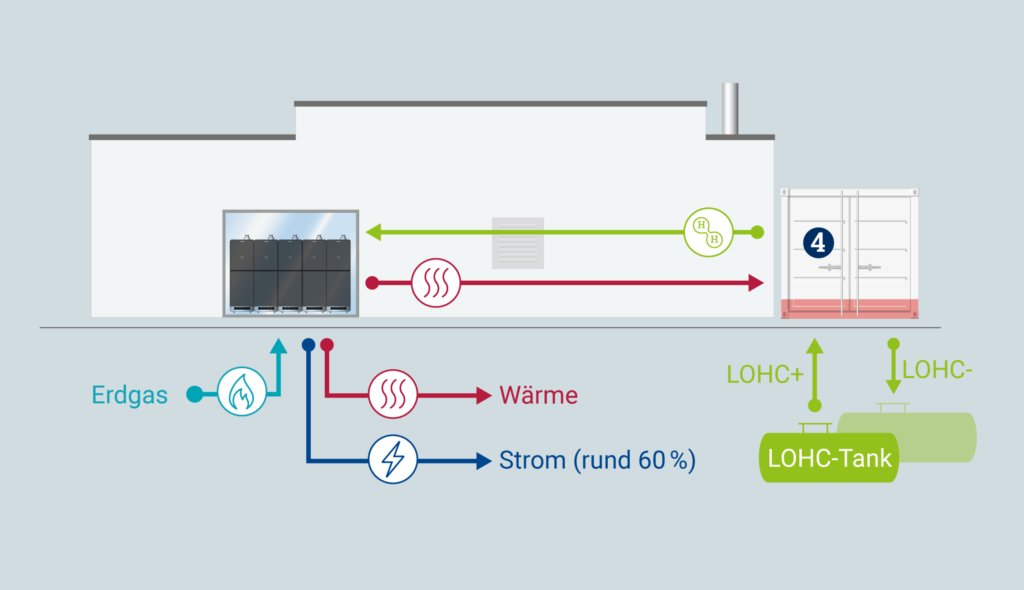

The first phase of the project with the commissioning of the ten SOFC units has been successfully completed. The SOFC system has initially been supplied with natural gas. The project partners have shown a significantly improved carbon footprint compared to the conventional power supply of the HJK with a combined heat and power plant. This is because the fuel cell system saves up to 40 per cent of CO2 emissions when running on natural gas. The reason for this is the higher electrical efficiency. In natural gas operation, the Bosch fuel cell system generates an electrical efficiency of up to 60 per cent. In comparison, the combined heat and power plant only achieves around 36 per cent.

Afterwards the project partners have started to add hydrogen to the natural gas, the proportion of which they are increasing step by step. The hydrogen is initially supplied under pressure in gas cylinders. As the proportion of hydrogen increases, CO2 emissions at the HJK continue to fall. The proportion in the gas mixture increases over time to up to 20 per cent. This provides insights for a possible later development of a supply based exclusively on hydrogen.

The energy centre is being rebuilt with an SOFC system (left) and LOHC technology.

Graphic: Research Centre Jülich/Reisen

In the next step, LOHC technology will replace gas cylinders. Until then, Hydrogenious LOHC NRW GmbH has installed its infrastructure at the HJK. This enables hydrogen to be delivered to Erkelenz in a conventional tanker lorry under ambient conditions. In order to release the hydrogen from the LOHC, energy in the form of heat must be supplied to the thermal oil. The partners want to show that it is possible to utilise the waste heat generated by the SOFC system when converting the gas mixture into electricity.

Once the hydrogen has been released, the discharged carrier material flows into a second underground tank. It can then be transported back to a hydrogen generator and recharged with hydrogen – similar to the returnable bottle principle.

The newly installed technology does not replace the hospital’s tried and tested supply. The HJK continues to use a combined heat and power unit and a gas engine as a fall-back option, which can also supply the building alone if required.

Anyone interested in finding out more about the Multi-SOFC project can send an e-mail to info.hch2@fz-juelich.de.

Animated film

Brochure

Our partners

Project status

150

Tonnes of CO2 saved

per year already in expansion stage 1

10

SOFC-Units

Number of SOFC modules installed

60 %

Electrical effiency

of the SOFC system

36 %

Electrical efficiency

conventional gas engine