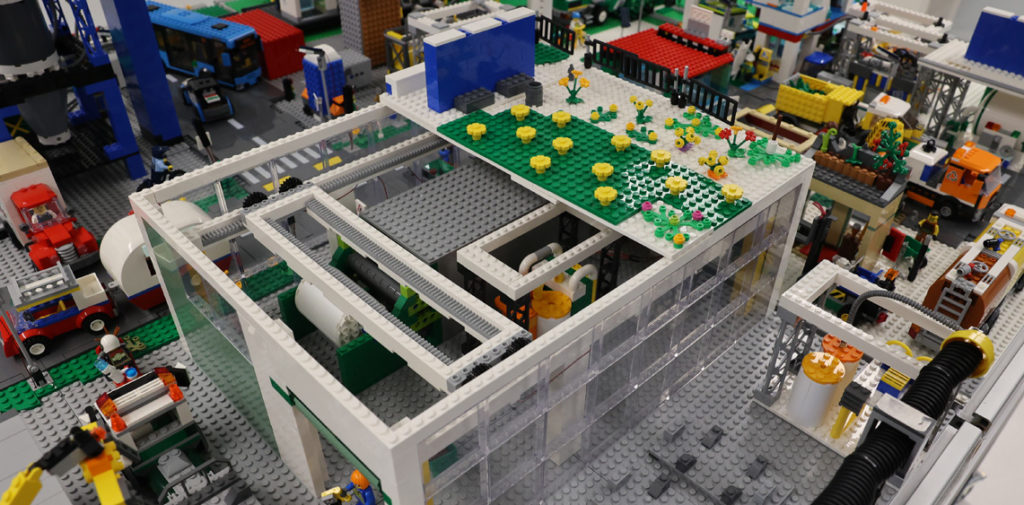

Demo systems in the

Lego model

You can find the complete overview of content and maintenance in this document.

The presentation on the main thematic lines of the INW and the HC-H2 and on the contents of the Lego model can be found in this PDF.

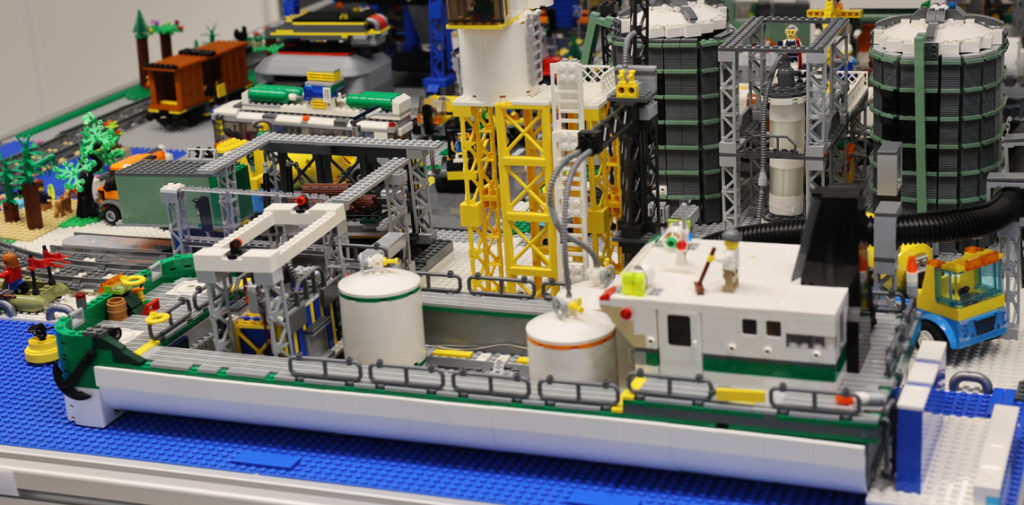

HECTOR

Europe’s largest and first industrial-scale hydrogen storage facility using benzyltoluene as a storage medium is being built at Chempark Dormagen. The project, called HECTOR, will store five tons of green hydrogen per day in a storage liquid called LOHC (Liquid Organic Hydrogen Carrier). The project partners are using benzyltoluene as the LOHC.

The green hydrogen is produced on site as a by-product during the production of the chemicals chlorine and caustic soda by means of chlor-alkali electrolysis.

With HECTOR, the hydrogen is stored in the carrier liquid and then transported from Dormagen to the port of Rotterdam. There, the hydrogen is released and used as an energy source. The heat generated during the loading process in Dormagen is integrated into the Chempark’s steam network.

Forschungszentrum Jülich is responsible for the accompanying scientific research within the project, focussing primarily on questions relating to the identification, separation and effects of impurities on the loading process as well as possible causes of these disruptive impurities.

The newly founded subsidiary of Hydrogenious LOHC Technologies, LOHC Industrial Solutions NRW GmbH, based in Krefeld, will be responsible for project management and operation of the plant. The parent company from Erlangen is supplying its patented and highly innovative LOHC technology. Covestro Deutschland AG is providing the site area in Dormagen and will supply green hydrogen in future. The scientific partner is Forschungszentrum Jülich with its Institute of Energy and Climate Research. A connection to the port of Rotterdam is also being prepared with the Dutch co-investor Royal Vopak.

Paper mill

The paper industry is of great importance in the Düren district with more than 10,000 jobs. The HC-H2 can imagine the paper industry as a project partner for two reasons: Paper production is an energy-intensive process. The wet paper webs, for example, have to be dried within a few seconds. As production often runs around the clock, the energy requirement is constantly high. It is therefore conceivable that in future, the energy supply will be ensured with the help of hydrogen technologies if no directly generated renewable energy is available. The paper industry is also a producer of biomass. Paper fibers that are too short to be reused after several recycling cycles can be used to produce hydrogen.

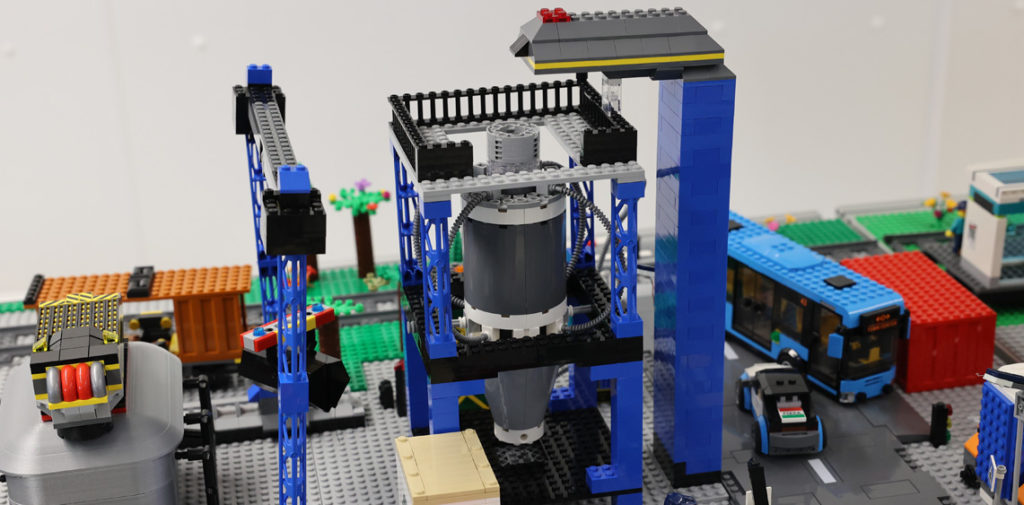

Inland navigation

Inland waterway vessels offer several potential applications for hydrogen. In the future, fuel cells could replace conventional ship diesel drives. The operation of ships can thus be made climate-neutral. Inland vessels can be refueled with chemically stored hydrogen. They are large enough to install the reactors that release hydrogen from the chemical carrier. This enables an operation that is logistically similar to the current diesel ship operation.

Furthermore, inland waterway vessels with their freight capacities can play a decisive role in the distribution of hydrogen. They are currently still doing this with fossil fuels such as coal or oil.

Agriculture

Agriculture has the potential to be both a user and a producer of hydrogen. Farms often have large areas of land on which renewable energy can be generated. In the future, this energy can be used to produce hydrogen when it is not needed to meet acute demand. The hydrogen produced in this way can then be used to power heavy machinery. With hydrogen as a storage medium, an energy self-sufficient and climate-neutral agricultural operation is conceivable.

Agricultural businesses also produce large quantities of biomass, which can be utilised in the future to produce hydrogen in biogas reactors.

Steel industry

A key production step in the manufacture of steel is the reduction of the iron ore by removing the oxygen contained in the ore. Up to now, this reduction has mostly been carried out using coke, whichproduces large quantities ofCO2 . One major goal is to replace coke with hydrogen. This is because hydrogen can also be used to remove the oxygen. The reaction product of steel reduction with hydrogen is therefore water vapor instead ofCO2.

This process is very energy-intensive overall. Replacing coke with hydrogen therefore saves large amounts ofCO2.

LEGO® is a trademark of the LEGO Group. The LEGO Group has not sponsored, endorsed or authorized this installation of LEGO bricks.