Demonstration project

HyHeat

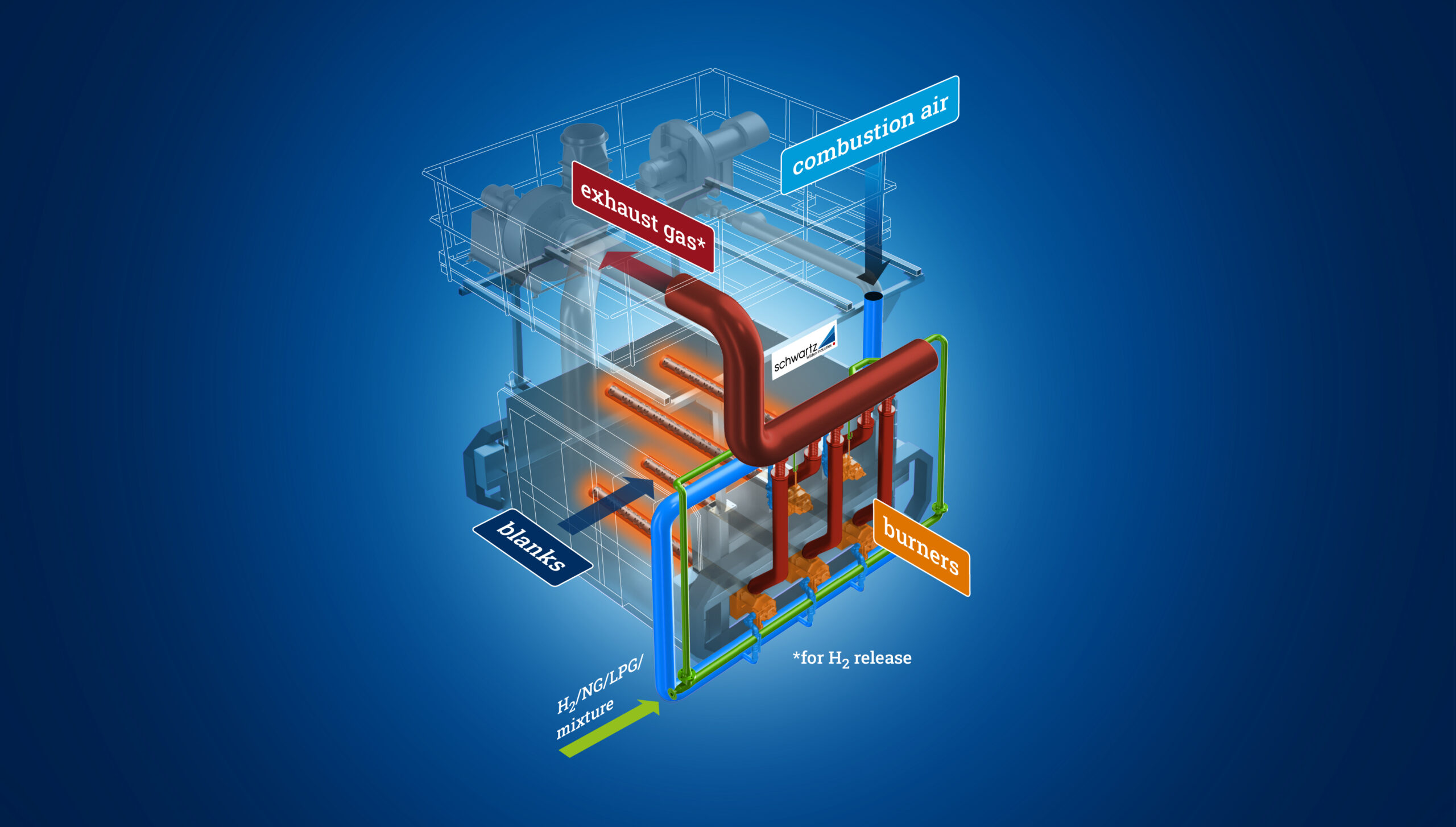

The HyHeat demonstration project shows how hydrogen can be optimally integrated as a fuel gas into the process of heat treatment. This opens up the possibility of ensuring the production of car body parts and other flat metal components in the future without climate-impacting emissions. © schwartz Gruppe

Climate-friendly combustion for heat treatmentKlimafreundliche Verbrennung für die Wärmebehandlung

Heat treatment is a proven method of changing the shape or hardness of metals. However, the industrial high-temperature processes required for this often produce large quantities of the climate-impacting greenhouse gas carbon dioxide (CO₂). This is where the HyHeat demonstration project comes in: the schwartz Group from Simmerath, the global market leader in heat treatment systems for press hardening, and Forschungszentrum Jülich are working together on solutions to reduce these emissions.

The CO₂ savings potential is huge: a heat treatment plant for press hardening generates up to 3,000 tonnes of CO₂ emissions annually. The Federal Ministry of Research, Technology and Space (BMFTR) is funding the project with £1.71 million out of a total volume of £2.44 million.

Management of the project

‘With HyHeat, we are demonstrating how an energy-intensive process such as metal processing can be made climate-friendly, predictable and competitive in the future.’

Philipp Morsch, coordinates the scientific monitoring of the HC-H2.

What happens here, technical details

At the heart of the demonstration project is the low-emission heat treatment of press-hardened metal blanks – cut or pre-punched sheet metal parts, such as those used as raw material in modern, lightweight automotive body construction. The metal blanks are heated to over 900 °C in a complex process. This allows them to be hardened and easily formed. This takes place in a subsequent process step in a cooled press tool. With the possibility of also using hydrogen as a fuel gas in the future, the schwarz Group is demonstrating a climate-friendly variant of heat treatment with combustion. At the heart of the process are innovative multi-fuel burners that can be operated with hydrogen, natural gas, propane or fuel gas mixtures for the first time without modifying the plant. The innovative burners were developed by the subsidiary Econova GmbH. By the end of 2025, the schwartz Group will have built a pilot plant with the multi-fuel burners at its headquarters in Simmerath. The pilot will then be demonstrated in operation as a preliminary stage for a possible larger heat treatment plant on an industrial scale.

The schwartz Group is building a demonstration plant in Simmerath by the end of the year, which represents a sub-area of a heat treatment plant. The plant demonstrates for the first time the possibility of switching seamlessly between several fuel gases.

© Forschungszentrum Jülich/schwartz Gruppe

As part of HyHeat, the Institute for a Sustainable Hydrogen Economy (INW) at Forschungszentrum Jülich is using simulations to test which storage technology is best suited when there is no pipeline supply of hydrogen on site. The INW team is particularly interested in chemical storage options in which hydrogen is bound into a larger molecule, making it easier to store and transport. A key aspect here is heat integration.

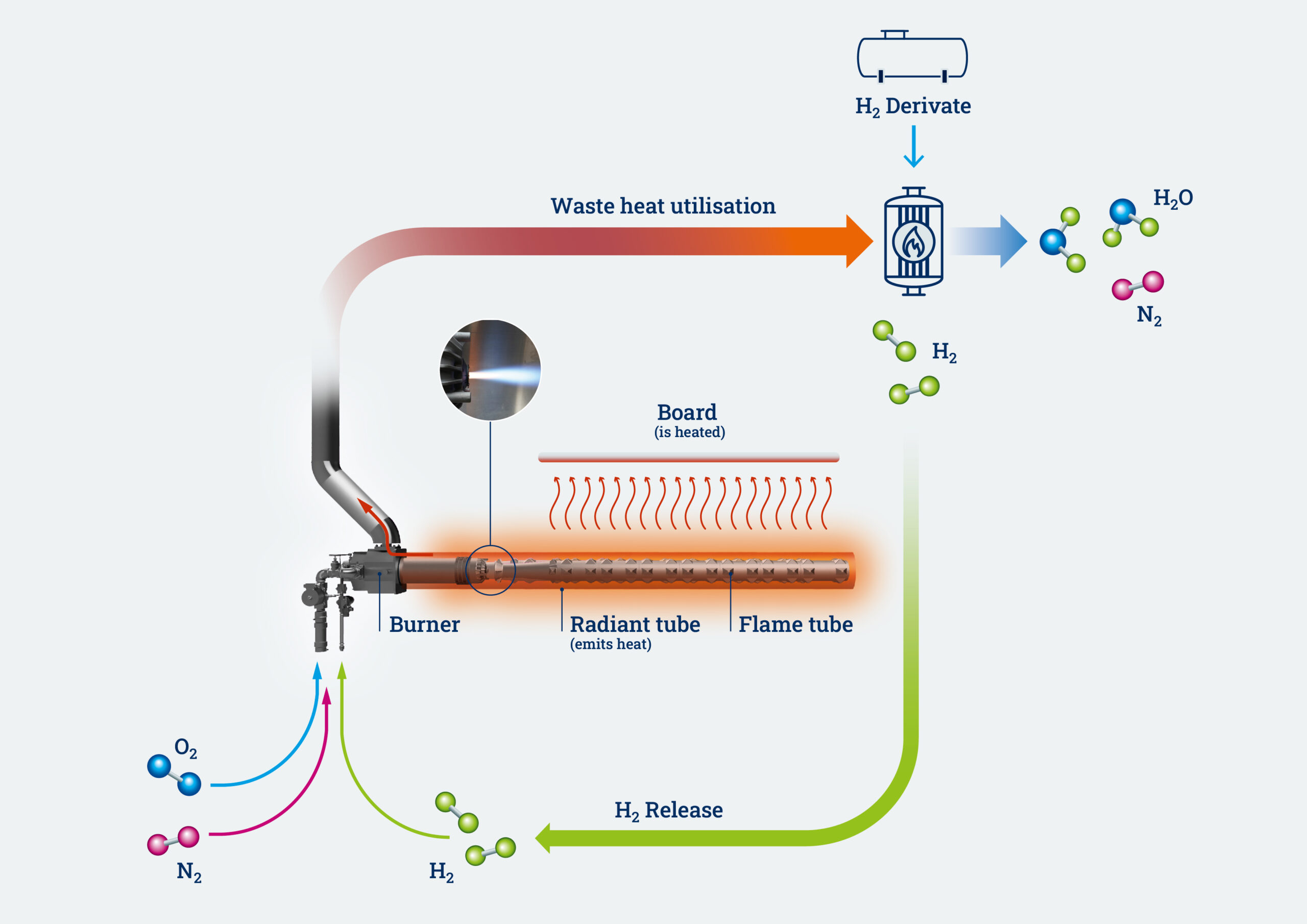

The heat treatment systems from the schwartz Group heat the plates indirectly. The burner flame heats a metal pipe from the inside, which then transfers the heat to the steel plate. The hot exhaust gas exits the pipe without coming into contact with the plates. ‘We want to use the energy contained in the exhaust gas for the process of releasing hydrogen from the larger molecule,’ says Philipp Morsch, who coordinates the scientific support provided by the INW.

Anyone interested in finding out more about the HyHeat project can send an email to info.hch2@fz-juelich.de

This is how the hydrogen operation of the innovative heat treatment plant can work: The multi-fuel burner uses hydrogen (H₂), which reacts with oxygen (O₂) from the ambient air. This generates heat, which is transferred to the substrate via the jet pipe. The product of combustion is water vapour (H₂O), which together with the non-reactive nitrogen (N₂) forms a hot exhaust gas. In future, the heat from this gas can be used to release hydrogen from a hydrogen derivative – a larger, hydrogen-based molecule. © Forschungszentrum Jülich/schwartz Group

Our partner

Project status

2.000

3

tonnes of CO2 saved

possible per year

Fuel gases

enable high flexibility and planning security