When metals need to change their shape or hardness, one thing is usually required above all else: heat treatment. However, the industrial high-temperature processes required for this often produce large quantities of the climate-impacting gas carbon dioxide (CO₂). This is where the HyHeat demonstration project comes in: the schwartz Group from Simmerath, the global market leader in heat treatment systems for press hardening, and the Jülich Research Centre are working together on solutions to reduce these emissions. At the heart of the project are innovative multi-fuel burners that can also be operated with hydrogen.

HyHeat is a project of the Helmholtz Cluster for Sustainable and Infrastructure-Compatible Hydrogen Economy (HC-H2), in which Forschungszentrum Jülich is cooperating with partners from the Rhineland mining region. The aim of HC-H2 is to accelerate the market entry of hydrogen-based, climate-friendly technologies and to create new economic power in the wake of the 2030 phase-out of lignite.

Global market leader from Simmerath

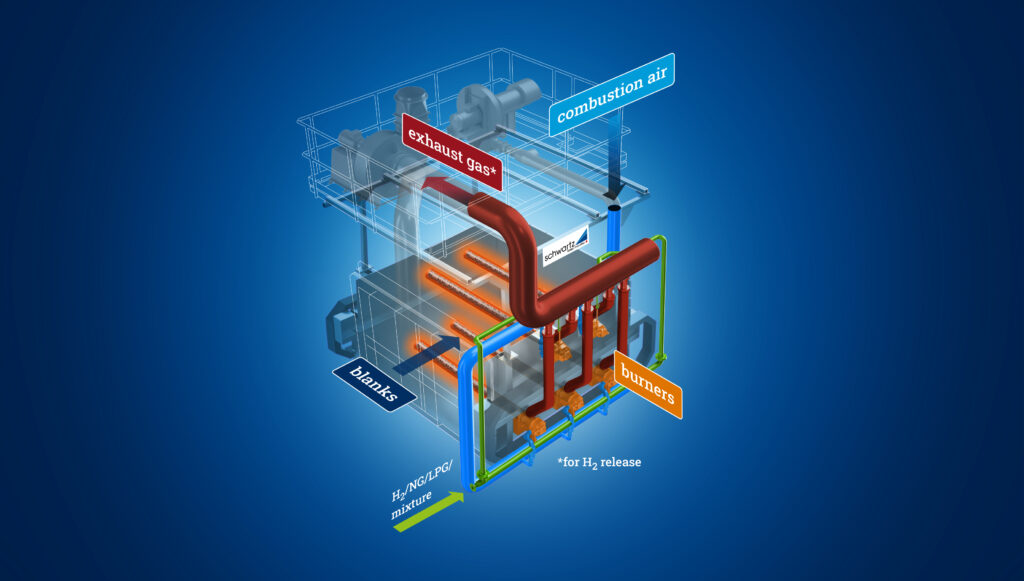

The schwarz Group, with 250 employees at 10 locations worldwide, has been developing and producing heat treatment systems for steel, aluminium and non-ferrous metals for over 40 years. At the heart of the demonstration project is the low-emission heat treatment of press-hardened steel blanks – cut or pre-punched sheet metal parts, such as those used as raw material in modern, lightweight automotive body construction. The steel blanks are heated to over 900 °C in a complex process. This allows them to be hardened and easily formed. This takes place in a cooled press tool in the downstream process step. The schwartz Group supplies industrial customers worldwide with the corresponding heat treatment systems.

By the end of the year, the company will install its first system at its headquarters in Simmerath whose burners can be operated with hydrogen, natural gas, propane or fuel gas mixtures. These so-called multi-fuel burners were developed by the subsidiary Econova GmbH.

Following the construction of the plant in Simmerath, demonstration operations will commence, during which the company and the Institute for Sustainable Hydrogen Economy at Forschungszentrum Jülich aim to demonstrate by the end of 2026 that flexible use of hydrogen-containing fuel gases is possible without compromising product quality. The Federal Ministry of Research, Technology and Space (BMFTR) is funding the project with €1.71 million out of a total volume of €2.44 million.

Technologies “made in Germany”

Dr Rolf-Dieter Jungk, State Secretary at the BMFTR, explains: “By funding this project, we are making an important contribution to climate-conscious metal processing. Hydrogen is the key to reducing the overall carbon footprint of metal components. What’s more, this demonstration project enables flexible industrial processes, reduces dependencies and anchors hydrogen in rural areas. Today, hydrogen research is supporting successful structural change in the Rhineland mining region – tomorrow, the results can be transferred to emission-intensive processes across the region. With this vision, we are jointly shaping the energy supply of the future: with technologies “made in Germany”, we are creating prosperity and protecting the climate.”

Dr. Rolf-Dieter Jungk, State Secretary at the Federal Ministry of Research, Technology and Space

Flexibility and CO2 savings

The potential for CO2 savings is huge: a heat treatment plant for press hardening causes up to 3,000 tonnes of CO2 emissions annually. “The demand for climate-friendly components is growing. In addition to electrically heated heat treatment, systems using combustion gases continue to be in high demand. We want to offer our customers the greatest possible flexibility in this area. With a plant such as the one we are demonstrating at HyHeat, customers will later have the option of varying the combustion gas composition during operation without modifying the heating system. The system automatically recognises the fuel gas or fuel gas mixture supplied and adjusts the combustion control to maintain a constant output,” says Frank Wilden, Technical Director at schwartz GmbH. The hydrogen-compatible system offers users long-term planning security, regardless of developments on the gas market.

“It is important to us to drive forward innovation in heat treatment systems. With the demonstration project and its subsequent practical application, we are making an active contribution to climate protection and showing our customers how they can integrate hydrogen,” says owner and managing director Alexander Wilden, explaining the group’s motivation.

The search for the right storage solution

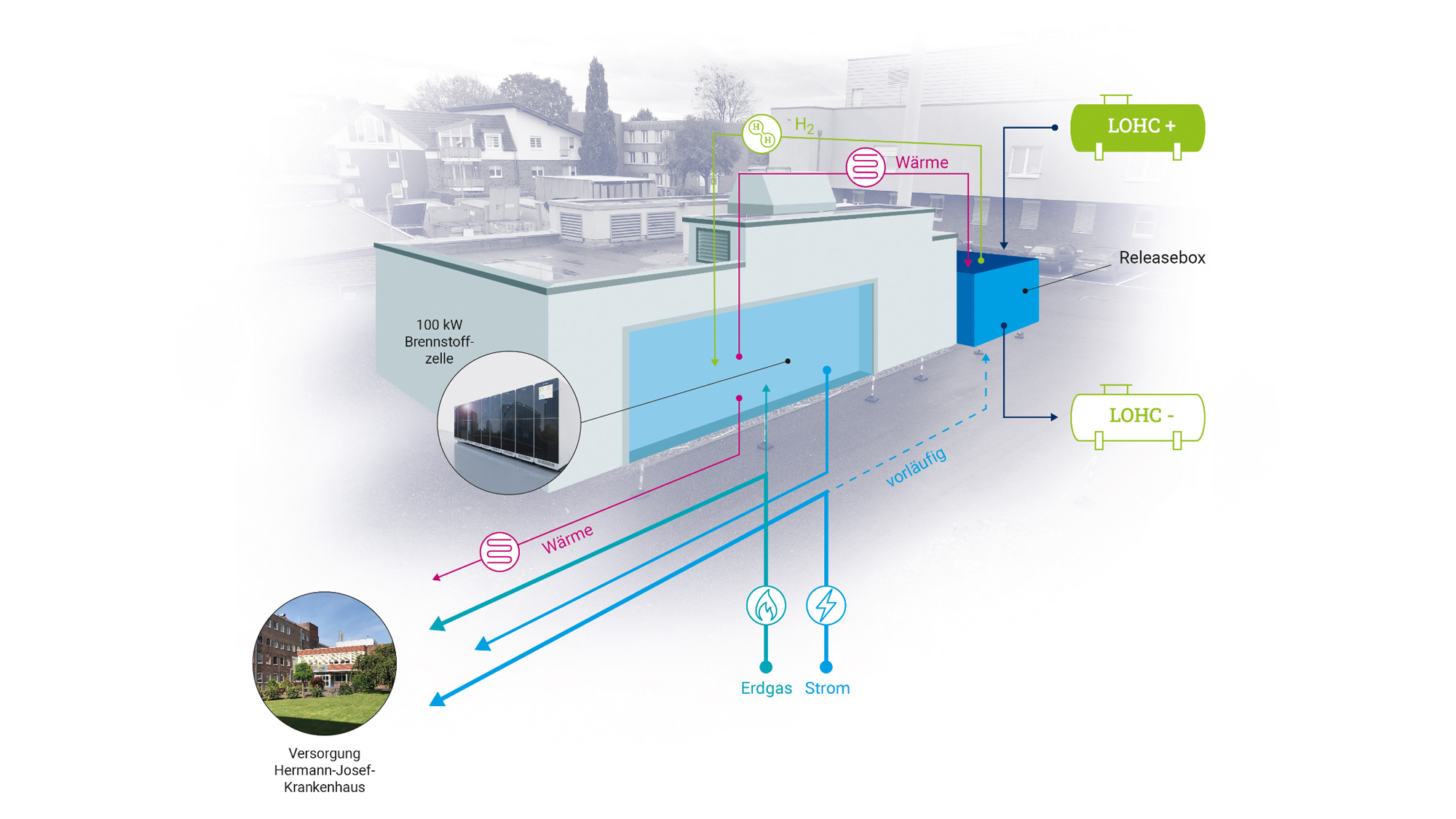

As part of HyHeat, the Institute for Sustainable Hydrogen Economy (INW) at Forschungszentrum Jülich is using simulations to determine which storage technology is best suited when pipeline supply of hydrogen is not possible. The INW team is particularly interested in chemical storage options in which hydrogen is bound into a larger molecule, making it easier to store and transport. A key aspect here is heat integration.

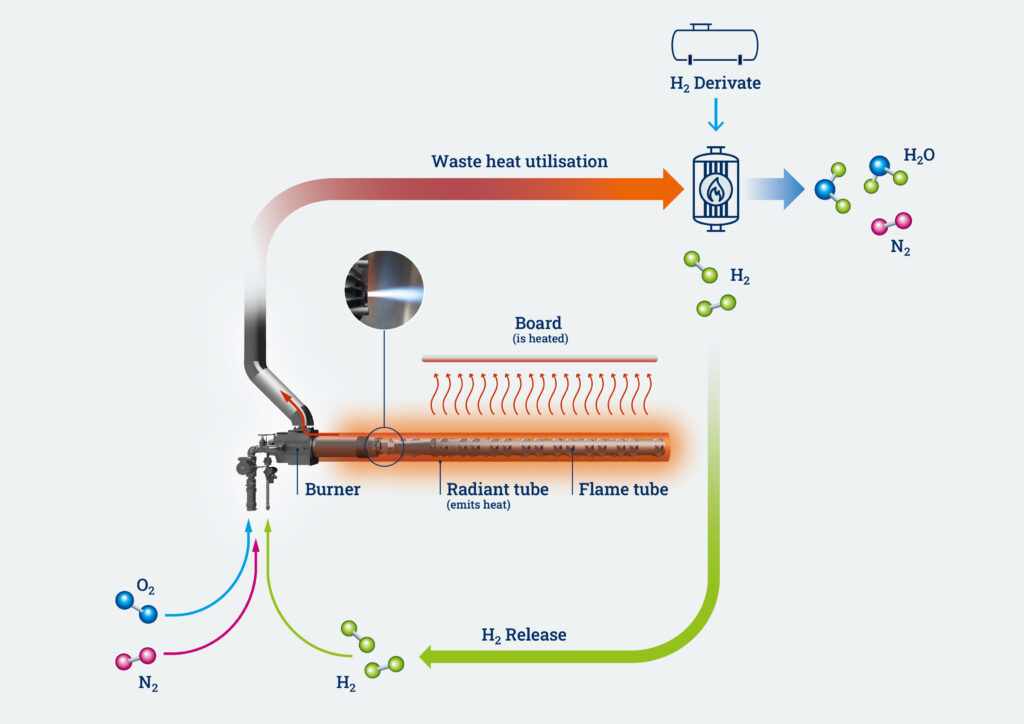

The heat treatment systems used by the schwartz Group heat the plates indirectly. The burner flame heats a metal pipe from the inside, which then transfers the heat to the steel plate via the outside. The hot exhaust gas exits the pipe without coming into contact with the plates. “We want to use the energy contained in the exhaust gas for the process of releasing hydrogen from the larger molecule,” says Philipp Morsch, who coordinates the scientific support for the INW. Temperatures of at least 290°C are necessary to release hydrogen from the carrier molecule. To this end, the previously unused waste heat is to be integrated.

“One challenge is the variable waste heat, as the burners are frequently switched on and off. We want to find out which chemical hydrogen storage system is best suited to these conditions,” explains Philipp Morsch. Chemical hydrogen storage systems are larger carrier molecules such as dimethyl ether, methanol or so-called LOHC (liquid organic hydrogen carrier), which bind hydrogen and release it when needed. The discharged carrier molecule remains behind and can be reloaded with hydrogen, similar to the principle of a returnable bottle. The loading and unloading process is called hydrogenation and dehydration, respectively. With such returnable bottle solutions, consumers without a pipeline connection can be supplied reliably in the future.

The copyright for the images used on this website is held by Forschungszentrum Jülich, aligator kommunikation GmbH and

stock.adobe.com.