The energy transition presents a major challenge for the chemical industry: until now, chemical plants have been continuously supplied with fossil energy and designed for stable, uniform operation. In the future, however, they must be capable of producing large quantities of key chemicals such as methanol in a climate‑friendly, efficient, and economically viable way under variable green energy supply conditions. Numerous scientific studies emphasize the need for greater operational flexibility in chemical processes, yet practical implementation remains limited.

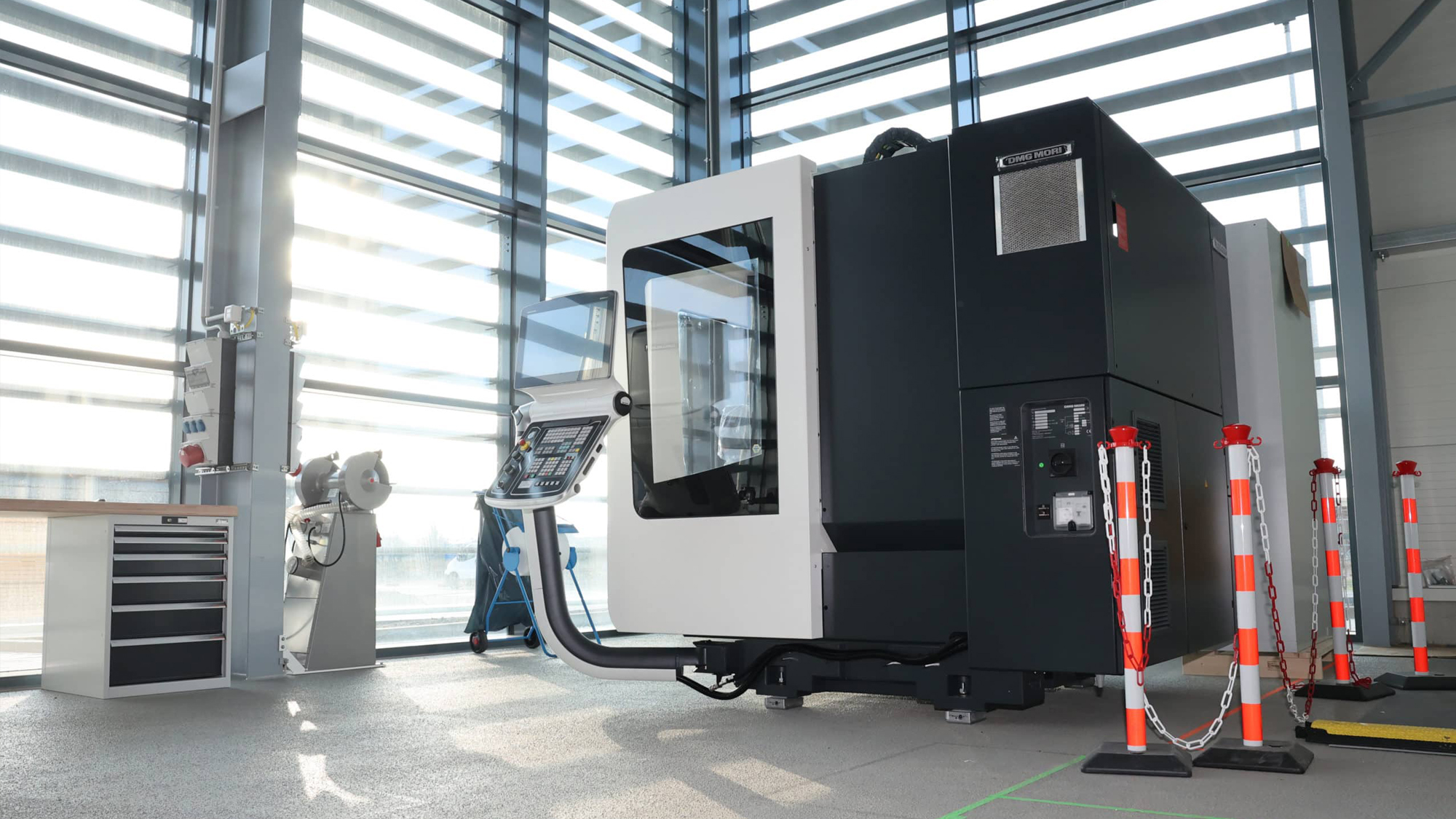

To address this gap, Forschungszentrum Jülich together with NEUMAN & ESSER and TLK Energy have joined forces in the newly launched HyControl funding project to demonstrate how the development process for future chemical plants can be significantly accelerated using a hardware‑in‑the‑loop (HiL) test rig.

HiL: Results even before the plant is built

“HiL simulates real operating conditions and delivers results even before a plant is built. This saves time and cost in the development of control systems for new climate‑friendly chemical plants,” explains Dr. Matthias Fischer from the Process and Plant Technology division (INW‑4) at Forschungszentrum Jülich’s Institute for Sustainable Hydrogen Economy. The aim is to transfer scientific insights into practice as rapidly as possible using HiL. The Jülich Institute of Energy Technologies (IET), specifically its Electrochemical Process Engineering division (IET‑4), is also actively involved in the project.

The project HyControl is funded over three years with a total of €1.96 million by the Ministry of Economic Affairs, Industry, Climate Protection and Energy of North Rhine‑Westphalia, co‑financed by the European Union within the framework of the Energie.IN.NRW innovation competition.

Long established in automotive and aircraft manufacturing

HiL technologies, already well established in the automotive and aerospace industries, integrate actual hardware into a simulated environment. For example, during aircraft autopilot development, the real autopilot control unit is embedded in a computer system that simulates flight conditions and data streams in real time. This enables developers to observe how the autopilot reacts to varying flight scenarios without flying an actual aircraft.

The HyControl consortium aims to transfer this strength of HiL to chemical process development. The goal is to adapt control strategies for future chemical plants as quickly and cost‑effectively as possible to fluctuating green energy inputs.

“HiL has scarcely been used in process engineering — there was neither acute demand nor robust dynamic models,” emphasizes Dr. Manuel Gräber from TLK Energy. As an engineering service provider and developer of simulation software, TLK Energy is developing a software package within HyControl to enable HiL simulations.

Load-flexible and local

Flexible load control is also crucial because future production landscapes will increasingly include smaller, decentralized plants directly coupled with local renewable energy sources such as wind and solar farms. Compared with today’s large fossil‑powered facilities, these plants are subject to far greater energy fluctuations. “Decentralized production units will play a significantly larger role in future energy systems. Our 5‑MW containerized electrolyzer meets this requirement. We see great potential in advanced control technologies that enhance the load flexibility of our modular systems,” says Dr. David Jasper of NEUMAN & ESSER, a provider of integrated hydrogen solutions. NEUMAN & ESSER will supply the electrolyzer model and the integrated automation and monitoring systems for HyControl.

At IET‑4, researchers are working on flexible control concepts for electrolyzers that produce green hydrogen from renewable electricity — a key precursor for green methanol. “While material research for electrolysis processes has made substantial progress, future electrolyzers must increasingly follow energy supply fluctuations. This requires intelligent operational concepts and control units capable of autonomously responding to the dynamics of renewable energy,” explains Prof. Ralf Peters from IET‑4.

The big goal: methanol synthesis

Building on the flexible electrolyzer, INW‑4 is using simulations to demonstrate how green methanol synthesis can be directly coupled to electrolysis. This substantially increases the demands on control and automation technology. Green methanol production requires two processes to respond to fluctuating energy inputs: electrolysis to produce hydrogen and methanol synthesis, where hydrogen reacts with carbon dioxide to form methanol. “We need complex control and automation technology, which we aim to develop and demonstrate,” states Dr. Urs Christen from INW‑4.

The copyright for the images used on this website is held by Forschungszentrum Jülich, aligator kommunikation GmbH and stock.adobe.com.