Lithium is a key driver of the battery boom – and thus of the energy transition – but global demand is growing faster than production. By 2030, demand is expected to double, and by 2040, to increase fivefold. Europe in particular, which is currently dependent on imports, faces a looming shortage. Three scientists from Forschungszentrum Jülich aim to change that. Their method is designed to extract lithium in a climate- and environmentally friendly way from previously untapped sources – including those in Germany. Their idea, called 7EX Technologies, is intended to evolve into a spin-off company.

Lithium is a cornerstone of the energy transition – indispensable for batteries in electric vehicles, storage systems, and smartphones. The lightweight metal enables long-lasting energy storage with high capacity. However, its deposits are unevenly distributed. Around 90 per cent of global production in 2023 came from Australia, Chile and China.

Extraction is also often problematic. In Australia, lithium is mined in energy-intensive open-pit operations; in Chile, it is extracted from salt lakes through evaporation – a process that consumes vast amounts of water and has significant ecological consequences, particularly in the Atacama Desert. China employs both methods. This leaves Europe in a dilemma: it depends on imports and competes with other regions for a limited supply. “Globally, around 240,000 tonnes of lithium were produced in 2024,” says Marten Huck from the Institute for a Sustainable Hydrogen Economy (INW) at Jülich. “By 2030, demand is expected to reach around 530,000 tonnes,” adds his colleague Andreas Kuhlmann. The growing demand amid stagnating production is leading to a shortage – the so-called lithium supply gap.

The Upper Rhine Graben as a Lithium Source

This is where 7EX Technologies comes in. The planned start-up from Forschungszentrum Jülich is developing a novel process for extracting lithium from aqueous sources such as geothermal and industrial process water. In the Upper Rhine Graben between Basel and Frankfurt, for example, there are several geothermal sources.

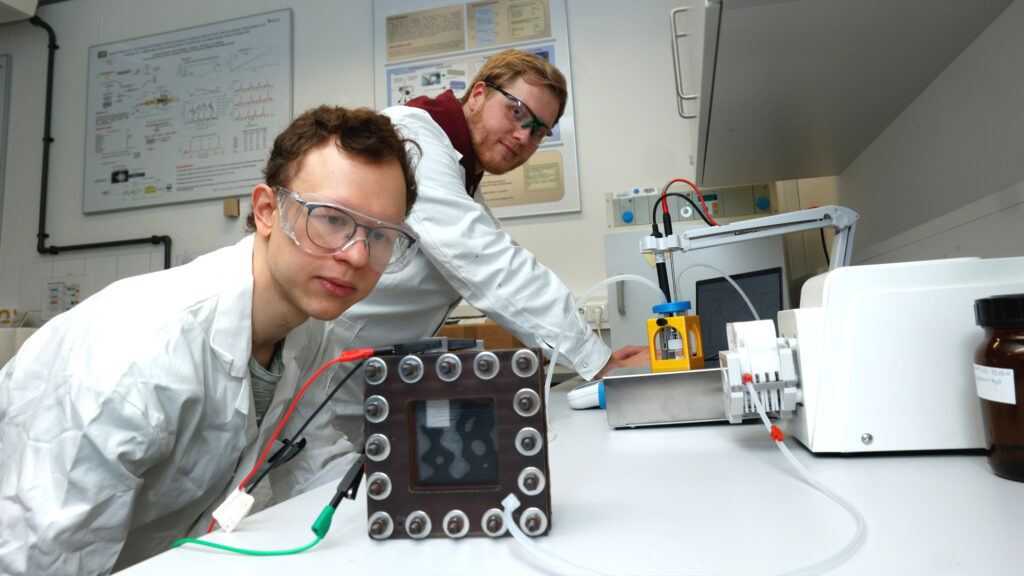

The technology’s developers – Andreas Kuhlmann, Marten Huck, and Prof. Hans-Georg Steinrück from the INW – have created an electrochemical process that selectively filters out lithium ions.

“We’ve designed a container into which the lithium-bearing water flows in, and lithium carbonate comes out,” explains Kuhlmann in simplified terms. Lithium ions accumulate on specially developed electrodes, while other, more common ions hardly react. The concentrated lithium is then separated as lithium carbonate – the compound that battery cell manufacturers can directly process further.

Resource-Efficient and CO₂-Neutral

“Our process runs on green electricity and is therefore CO₂-neutral. We use less water, less energy, and less material,” adds Steinrück. The lithium concentration in geothermal water is around 500 times higher than in seawater, the researchers emphasise.

“To produce one tonne of lithium carbonate, we need about an Olympic-sized swimming pool full of geothermal water,” explains Huck. Unlike conventional lithium extraction, the water is not consumed.

For their concept, the Jülich team received the AC² Start-up Award of the Aachen region. The jury praised both the scientific excellence and the economic potential of the project. Shortly afterwards came further success at the JUICE Innovation Contest of Forschungszentrum Jülich, which recognises ideas with strong application potential.

7EX Technologies is pursuing a decentralised approach: instead of large industrial plants, compact, self-sufficient modules are to extract lithium directly at geothermal or industrial sites – low in emissions, efficient, and independent of global supply chains.

Patent applications are already under way, and a pilot plant is planned within the next three to four years. The name refers to the chemical basis: “7” stands for lithium’s molar mass, and “EX” for extraction.

The copyright for the images used on this website is held by Forschungszentrum Jülich, aligator kommunikation GmbH and stock.adobe.com.