The stock of machinery continues to grow at the Institute for a Sustainable Hydrogen Economy.

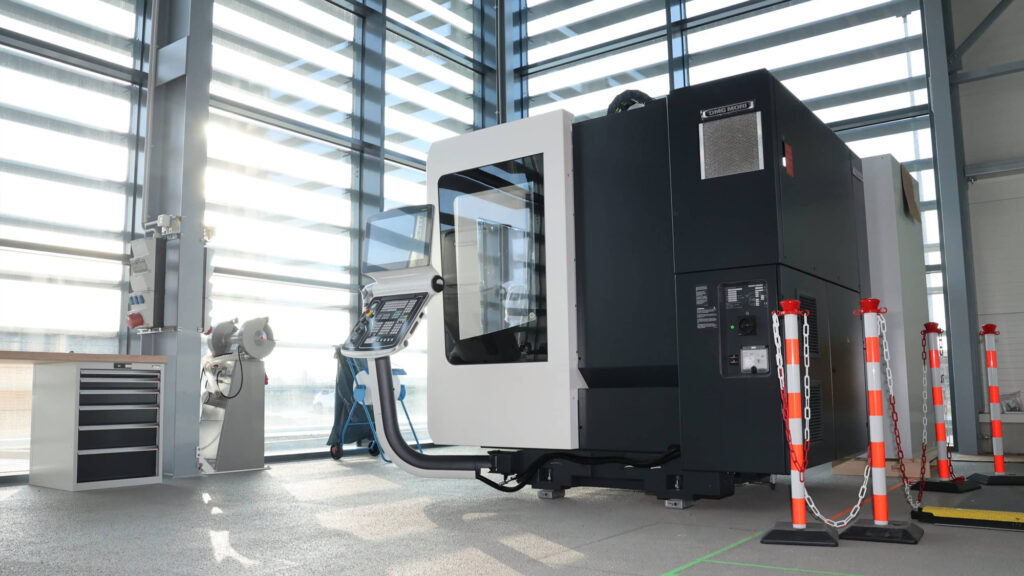

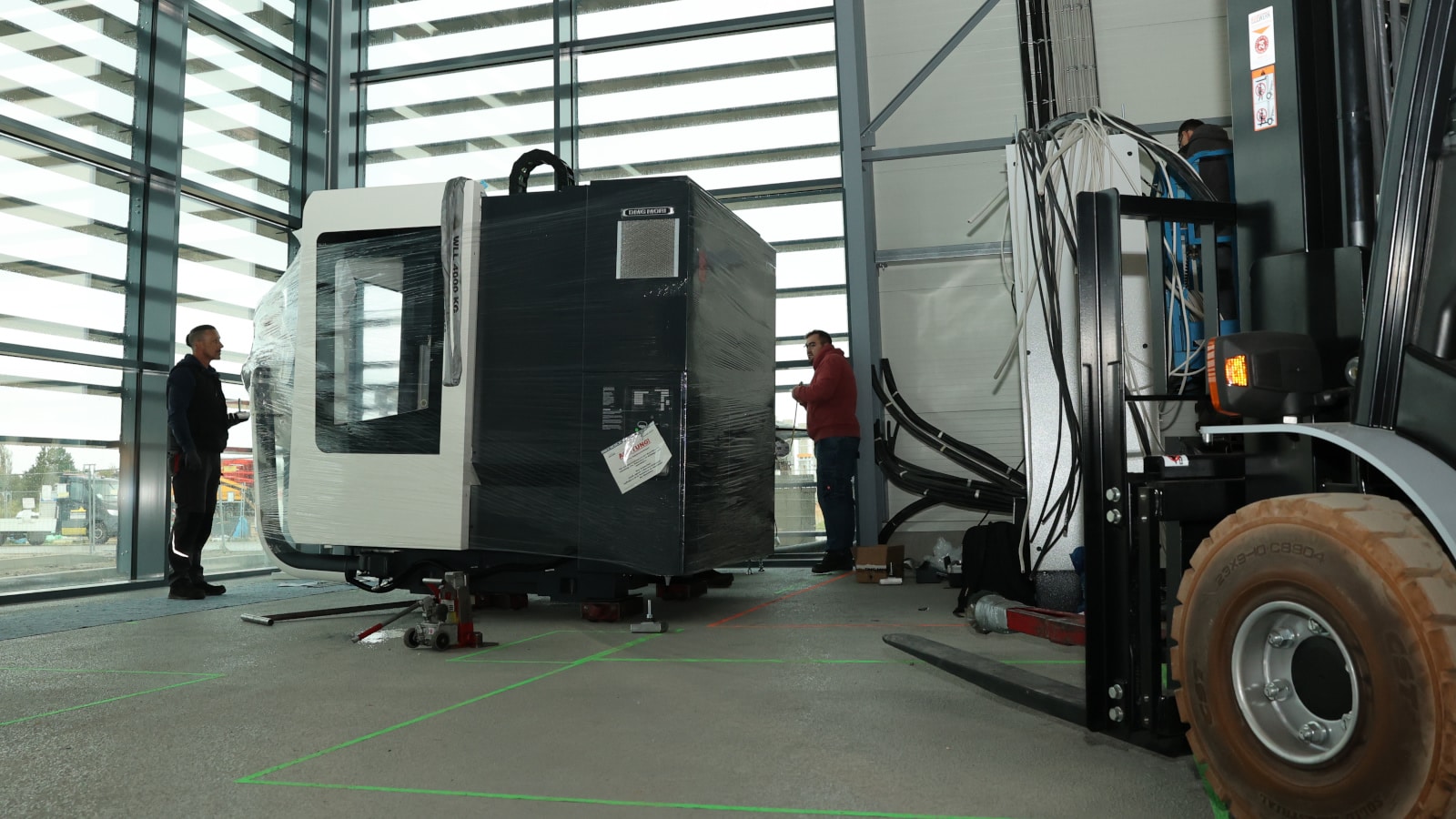

Jülich hydrogen researchers recently acquired another important tool. For a few days now, a 5-axis CNC milling machine has been part of the stock of machinery at the Institute for a Sustainable Hydrogen Economy (INW). “This milling machine is undoubtedly one of the highlights in our workshop,” says Jannis Fahnenschreiber, head of the INW workshop, which is currently being set up and is expected to be fully operational by mid-2024.

INW is the most recent institute to be established at Forschungszentrum Jülich. However, it is not located on the campus of the major research institution, but instead in the innovative Brainergy Park industrial estate. One of the reasons for this is that INW should be easily accessible without a surrounding fence for anyone interested. Major developments are taking place almost every week at INW. In autumn, the institute took over the technical centre (pictured left). Interior construction work is now underway, and a workshop is being set up. The milling machine manufactured by DMG Mori is one of the most important tools in the workshop.

“The milling machine is undoubtedly one of the highlights in our workshop.”

Jannis Fahnenschreiber

Construction of customized prototypes

“We can use it to produce individual components for our experimental set-ups that are not available to buy,” explains Fahnenschreiber. This ensures that both setting up and experimenting with new kinds of systems are faster, as the workshop team is able to manufacture customized prototypes, Fahnenschreiber adds. The milling machine weighs 5.5 tonnes in total and features five movable axes. “We can use it to manufacture precise parts capable of reaching the highest tolerance grades. We also do not need to keep reclamping the parts due to the flexibility of the milling machine. This saves time.”

There are also plans to install a vertical lift system, which has a high storage capacity but takes up little space, as well as a lathe and another conventional milling machine. Machines dedicated to sheet metal working and cutting bars and profiles can already be found in the workshop.

Marketing innovative hydrogen technologies

One of INW’s goals is to build innovative systems based on novel hydrogen technologies in the technical centre, which can then be demonstrated in cooperation with partners. The Helmholtz Cluster for a Sustainable and Infrastructure-Compatible Hydrogen Economy (HC-H2) is being established by INW and its partners. One of the cluster’s aims is to develop and demonstrate innovative hydrogen technologies in collaboration with partners. The partners should then be in a position to market the technology.

The copyright for the images used on this website is held by Forschungszentrum Jülich, aligator kommunikation GmbH and

stock.adobe.com.