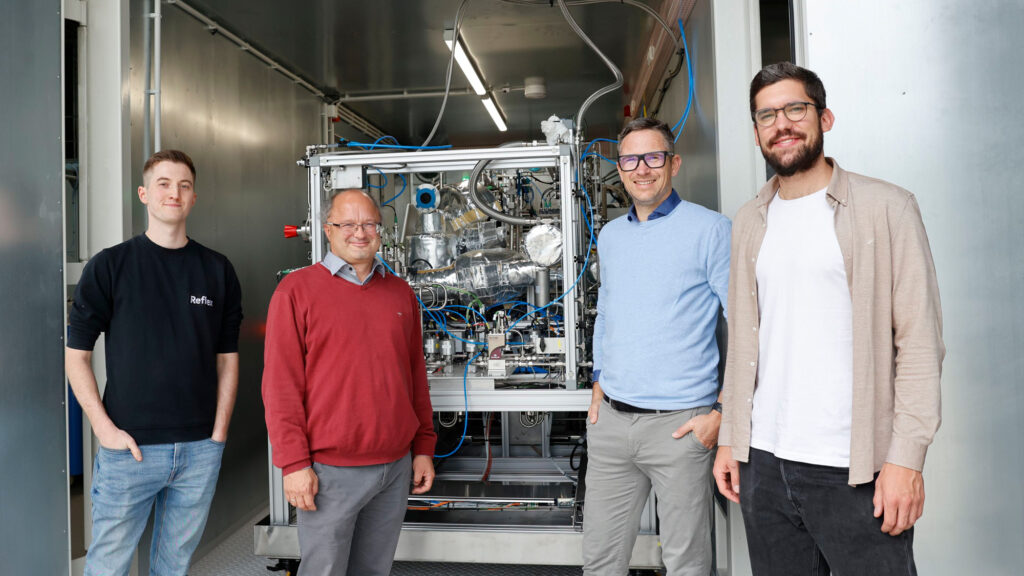

Clean H2eat and Reflex Paper plan industrial demonstration of hybrid steam generator in Düren

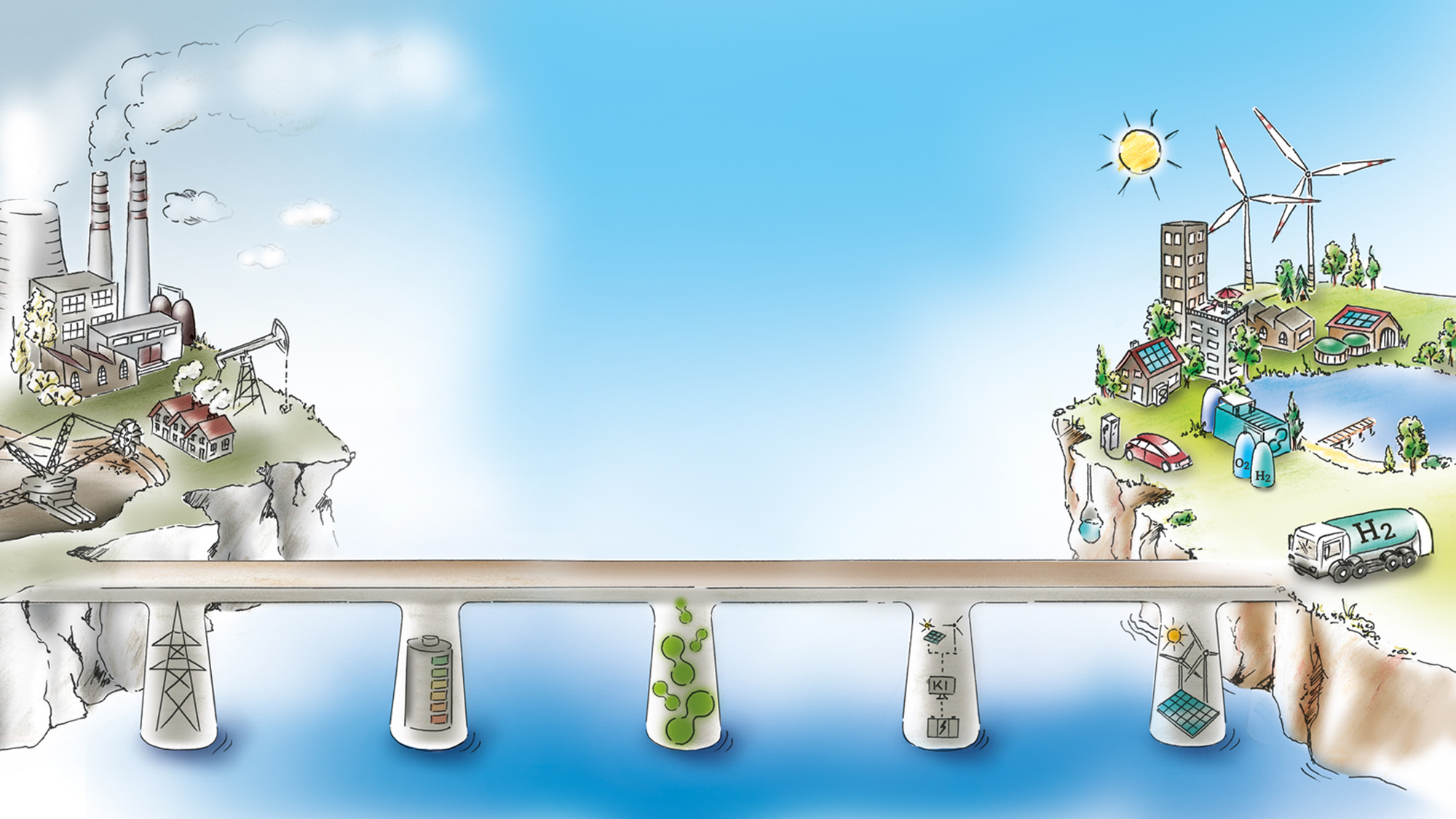

Reflex GmbH & Co. KG, a leading global manufacturer of high-quality speciality papers based in Düren, is teaming up with cleantech start-up Clean H2eat as part of a pioneering pilot project. Together, the partners are bringing a hybrid steam generator into industrial use for the first time, enabling flexible and emission-free industrial heat supply for paper drying.

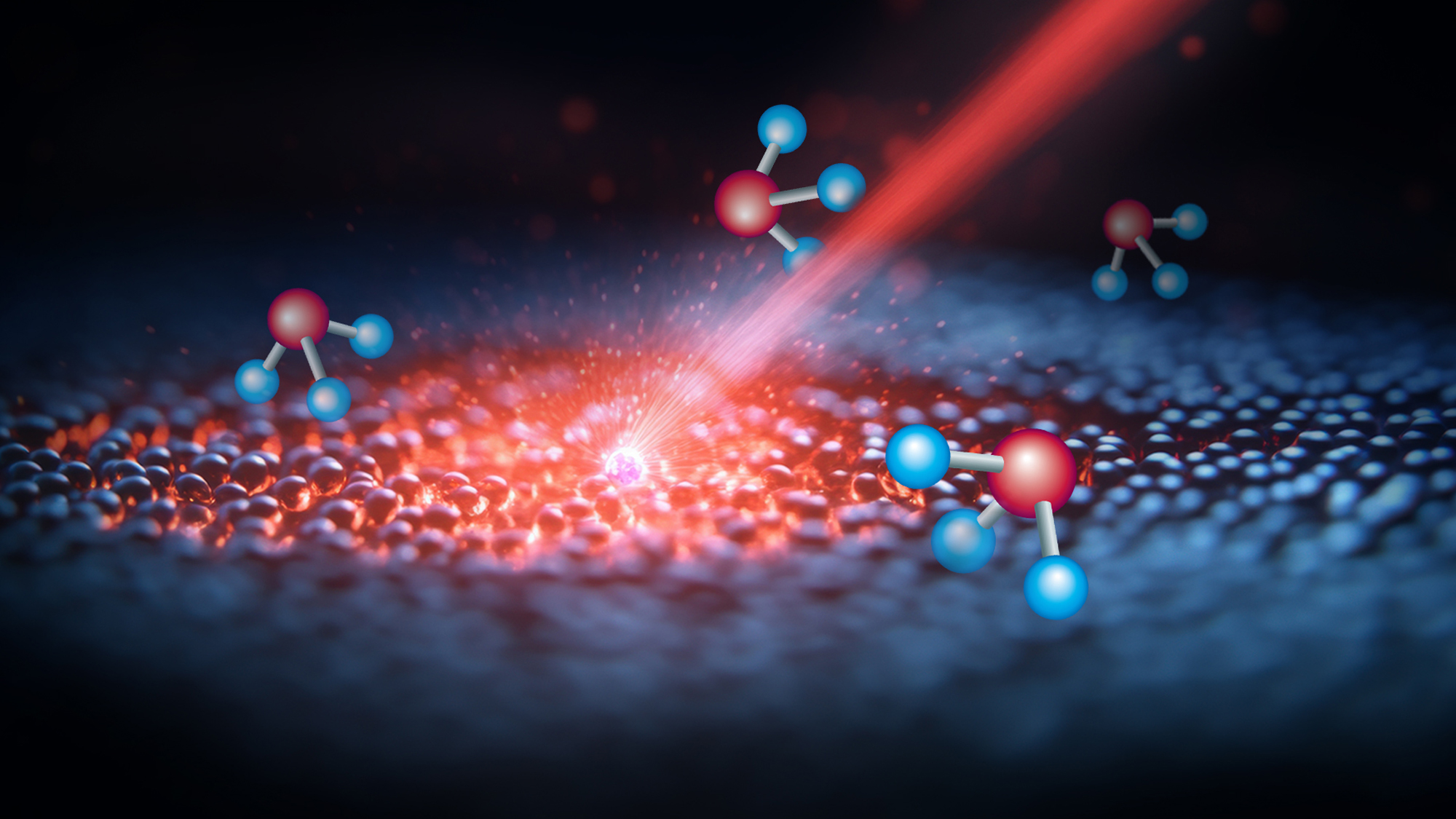

The steam generator from Clean H2eat is designed for the future and combines electric heating with catalytic combustion, achieving maximum efficiency, zero NOX emissions and – when using green electricity and green hydrogen – zero CO2 emissions.

Reducing emissions and costs

“We want to further reduce our emissions and offer our customers more sustainable products,” explains Dr. Tiemo Arndt, Managing Director of Reflex GmbH & Co. KG. “And for our process heat, Clean H2eat offers a very promising, integral approach – regardless of where and how quickly the energy landscape develops.”

In addition to reducing emissions, the partners also want to lower the costs of process heat. For this purpose, the demonstrator is equipped with an intelligent control unit that automatically switches between electricity and natural gas/hydrogen depending on the market environment. This allows volatile electricity prices and electricity from own generation to be used cost-effectively and reduces steam costs.

“Important milestone”

“The collaboration with Reflex Paper as a pilot customer is an important milestone for us,” explains Dr. Simon Hahn, Managing Director of Clean H2eat. “With this project, we are scaling up our technology and putting it through its paces in a practical setting at the customer’s premises.”

Clean H2eat will start detailed planning and construction of the demonstrator together with partners as soon as financing is secured. Commissioning is planned for 2027.

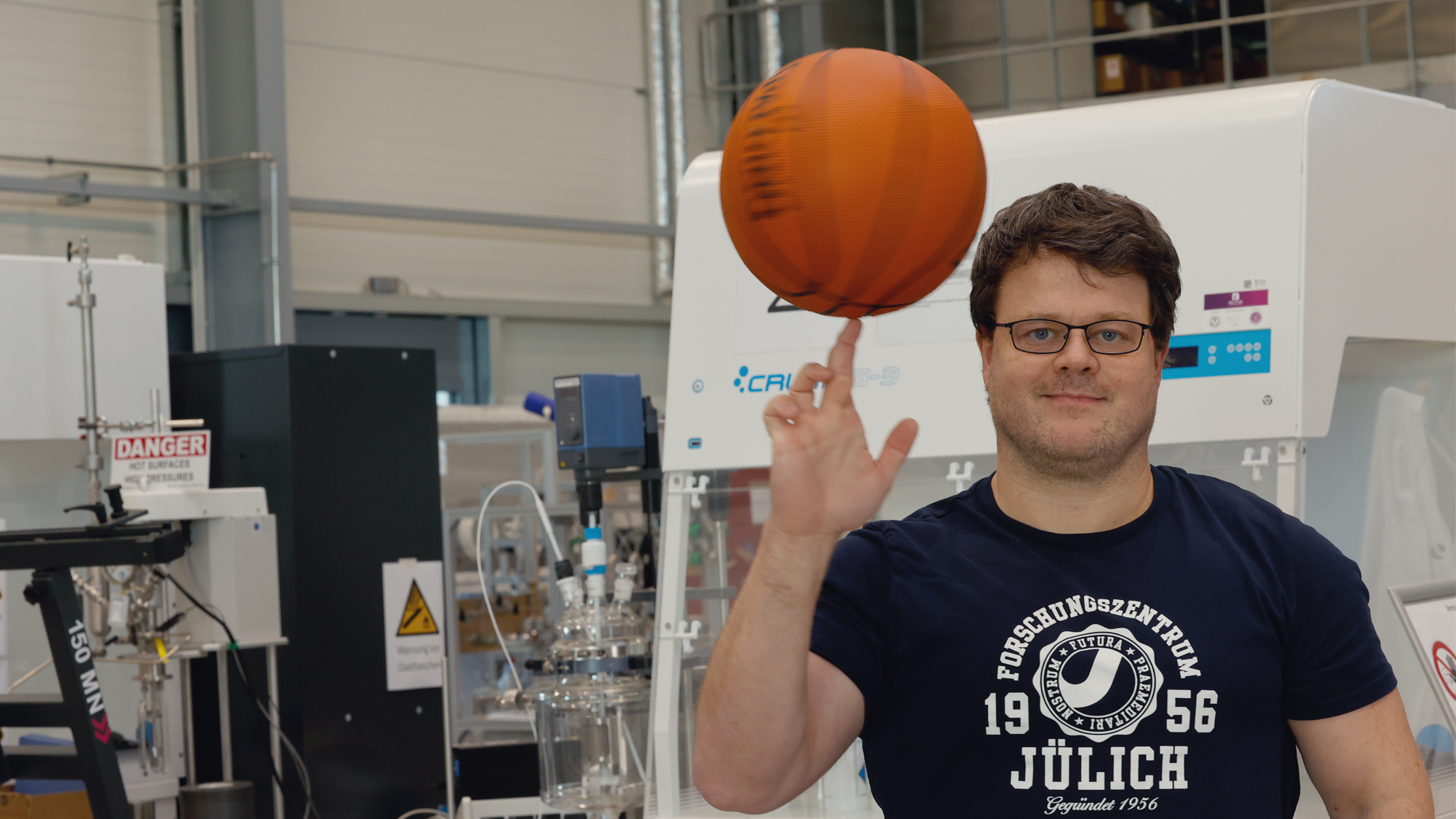

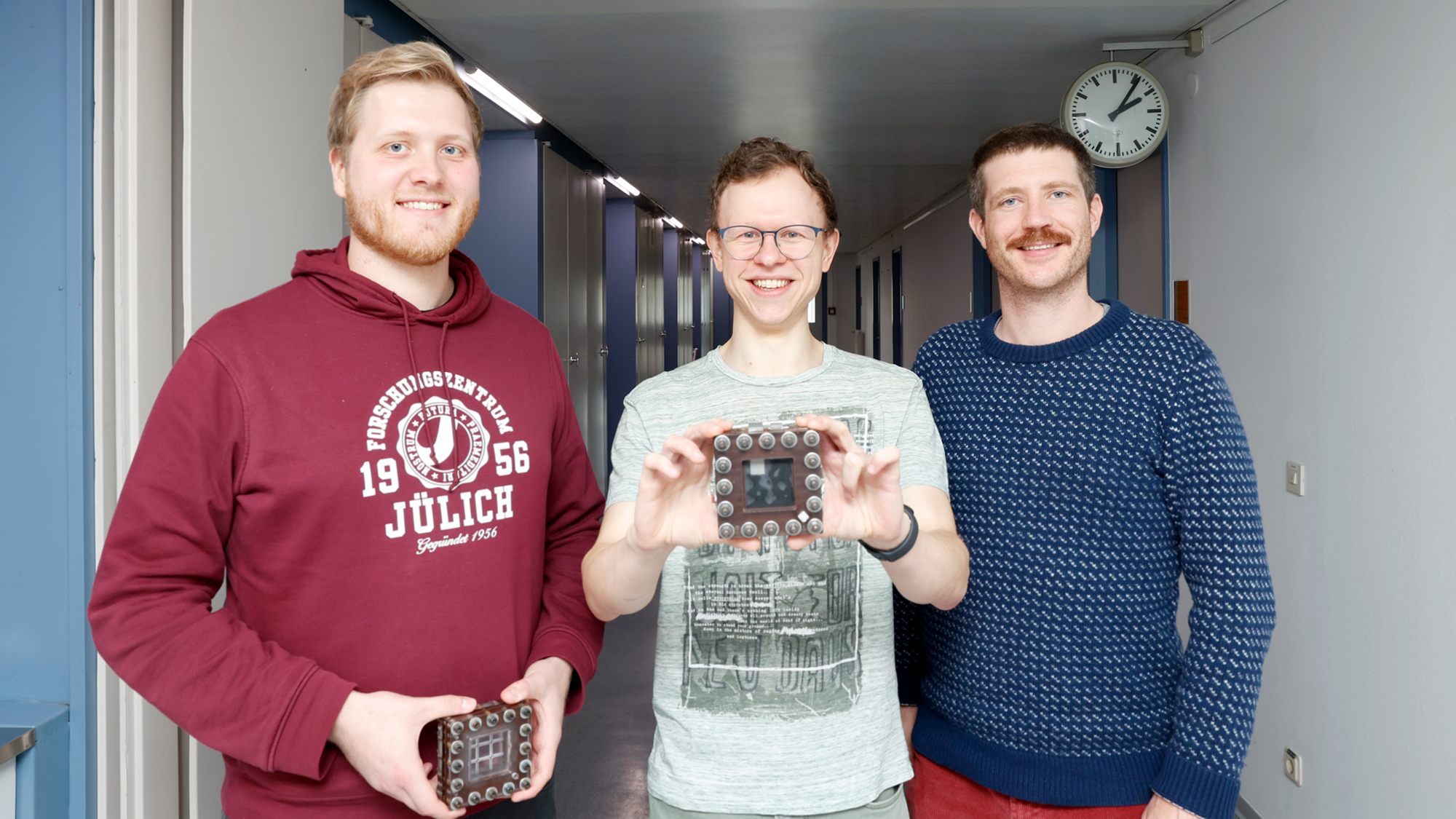

About Clean H2eat

Clean H2eat is a young technology spin-off from Forschungszentrum Jülich and aims to decarbonise process heat in industry. The company offers flexible, future-proof heating systems for industrial process heat that dynamically use the most cost-effective energy source – natural gas, electricity or hydrogen – to reduce emissions and operating costs.

About Reflex

Reflex GmbH & Co. KG has stood for the highest quality in paper manufacturing for decades. The company combines traditional craftsmanship with modern, sustainable production processes and supplies customers worldwide with speciality papers for various applications.

The copyright for the images used on this website is held by Forschungszentrum Jülich, aligator kommunikation GmbH and

stock.adobe.com.