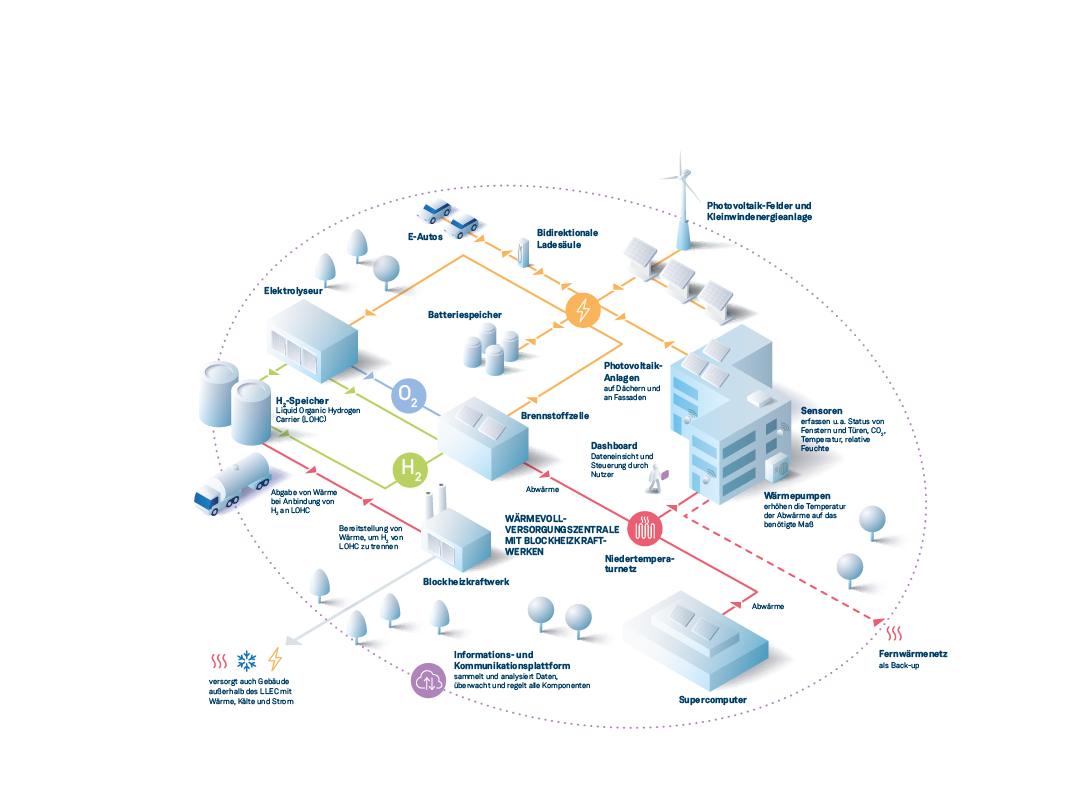

In the future, we will use many decentralised energy systems to meet our needs. In this context, it will be essential to optimally link all sectors. Experts from Jülich are testing how this can be done most efficiently in practice. To do this, they are transforming the campus of Forschungszentrum Jülich into a real-world laboratory. Hydrogen is an important pillar in this endeavour, helping to support the energy system of the future. In Jülich’s real-world laboratory – and one day worldwide.

‘Even in times of scarce and expensive energy, you don’t have to sit in a cold office in the morning in winter,’ says physicist Dr. Stefan Kasselmann. ’When you come to work in Jülich in the future, the heating will already be on and your room will be comfortably warm – and with lower energy consumption.’ This is already being tested in some buildings and works because the energy is used as needed. The key to efficiency: intelligent networking and largely automated control. ‘This is exactly what we are currently testing in real-life operations on the Jülich campus,’ says Stefan Kasselmann, head of the Intelligent Campus department at Forschungszentrum Jülich.

The team is taking on board new findings in the fields of energy, digitalisation and mobility and implements them in the research centre’s infrastructure where suitable. One of the Intelligent Campus team’s major topics is the Living Lab Energy Campus (LLEC) project. The aim of the LLEC is to investigate highly coupled, intelligent energy systems in terms of feasibility, sustainability and user comfort, which can also be operated economically by scaling them appropriately.

Dr. Stefan Kasselmann, head of the Intelligent Campus division. Photo: Forschungszentrum Jülich/Kreklau

Like a small town

Hydrogen plays a major role here, for example as a chemical energy store, when it comes to areas where electrification does not seem technically feasible or economically viable. ‘We want to use the LLEC to test under application-oriented conditions how energy can be efficiently distributed and used in the future within a district or a small settlement. Around 7,000 people work at the Jülich site, which is comparable to a small town. There are offices, laboratories and various other types of use. This allows us to recreate different scenarios in a real-life environment, from industrial areas to residential neighbourhoods.’

At the moment, the energy supply in Germany is still partly characterised by large power plants that burn fossil fuels such as coal, oil and natural gas to generate electricity and heat. But wind and solar power are clearly on the rise. Last year, for the first time, more than half of the electricity produced in Germany was green. In the future, green electricity will dominate the energy grid. This means many small, decentralised producers. ‘We also talk about sector coupling here. A good example of this is the low-temperature grid on campus, which will be successively put into operation this year. It also shows how sources that have not been considered so far can be integrated so that as little energy as possible remains unused,’ explains Stefan Kasselmann.

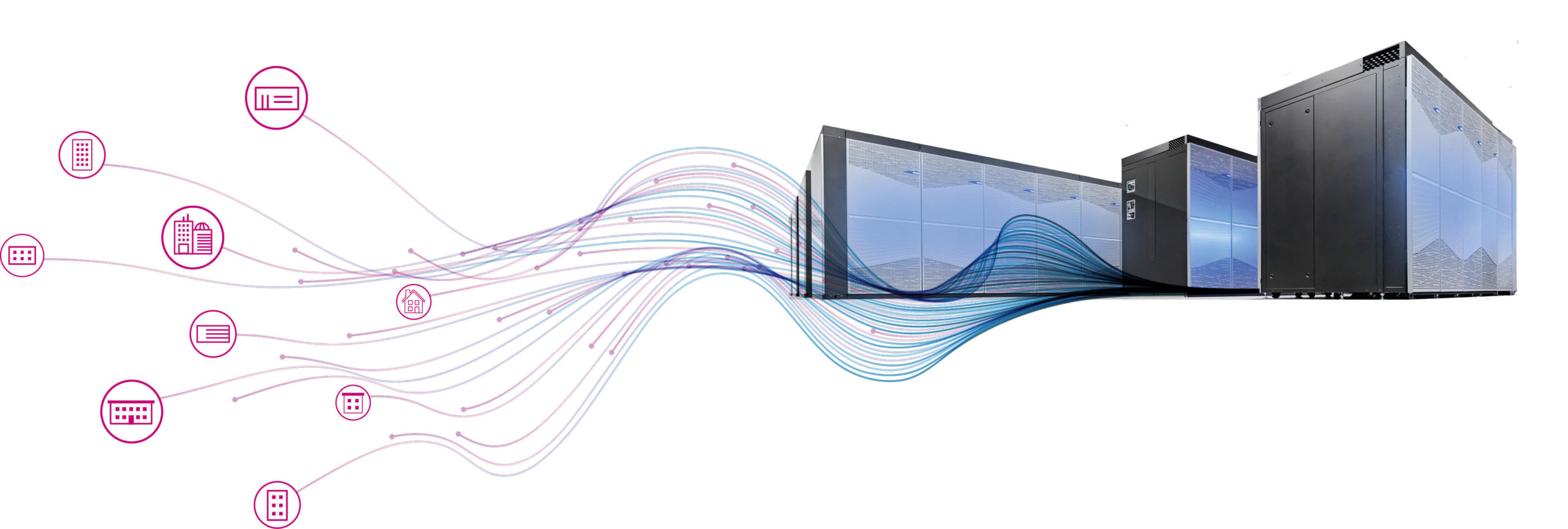

Another major project for the Intelligent Campus team is the new supercomputer system JUPITER (Joint Undertaking Pioneer for Innovative and Transformative Exascale Research), which is currently being installed and is scheduled to start regular operation in 2025. JUPITER will be the first exascale computer in Europe, capable of a quintillion computing operations per second. That’s a number with 18 zeros. It is important to the researchers at the Jülich Supercomputing Centre (JSC) that the system is not only fast but also energy-efficient. A first module of the computer, which has been running since the spring, occupies first place on the list of the most energy-efficient supercomputers in the world. ‘Together with other departments, we are working on the ExaHeat project to gradually integrate the system’s waste heat into the campus heating network in the multi-megawatt range. We want to have built the waste heat centre necessary for this by 2027,’ says Stefan Kasselmann.

In the future, the waste heat from the JUPITER supercomputer will be fed into the Jülich research centre’s energy system. Graphic: Forschungszentrum Jülich/Reisen

Heating with waste heat

From next year, the low-temperature network will supply the JSC and eight surrounding buildings with heating. The heating energy comes from the cooling of the JUWELS (Jülich Wizard for European Leadership Science) supercomputer, which is currently still the fastest Jülich computer. When highly complex simulations are running on its processors, the electronics give off a lot of waste heat to the cooling water. The now warm liquid is then fed into the low-temperature network on campus and distributed.

‘The water has a temperature of almost 40 degrees Celsius,’ explains Dr.-Ing. André Xhonneux from the Institute of Climate and Energy Systems (ICE-1, Energy Systems Technology), who is responsible for the software and simulation team at the LLEC. The water, which is just hand-warm, can be used without any problems to supply the energy-efficient new building. But it is too cold for the heating systems of older buildings: ‘Older buildings require water heated to up to 85 degrees Celsius to provide all rooms sufficiently. That’s why we use heat pumps to bring the water up to that temperature,’ says mechanical engineer André Xhonneux.

Dr.-Ing. André Xhonneux from the Institute of Climate and Energy Systems (ICE-1, Energy Systems Engineering), responsible for the Software and Simulation team at the LLEC. Photo: Forschungszentrum Jülich/Kreklau

‘This also allows us to continue using the buildings‘ old heating systems for the time being.’ This is particularly important for transferring the knowledge gained at the LLEC to urban neighbourhoods. There, the waste heat could come from companies and businesses: ‘Here in the region, for example, the sugar factory in Jülich comes into question. But there are also countless untapped sources that can be identified using the German heat register.’

‘We have installed photovoltaic systems on campus that are technologically very diverse. Together, they generate a peak output of around 1.5 megawatts. These generation systems will determine the dynamics of the entire virtual energy system of the LLEC and thus the operation of all other LLEC demonstrators, while also contributing to the sustainable energy supply of the campus,’ says Stefan Kasselmann.

New photovoltaic lightweight construction systems

Some of the solar modules are located in an open space, while the rest are distributed across various buildings on campus. ‘In new buildings, the systems are easy to integrate,’ explains Dr Andreas Gerber from the Institute of Energy Materials and Devices (IMD-3 Photovoltaics), LLEC team manager for the field of photovoltaics. ‘Either on the roof, as semi-transparent modules in the skylights or in the façade. But of course we would also like to continue equipping existing buildings with them.’

At Forschungszentrum Jülich, this has proven to be a challenge because many roofs already support infrastructure for the laboratories below: air conditioning and air purification systems, for example. This reduces the size of contiguous areas and provides shade. Other roofs were not designed to carry such a high load. In an urban area, however, the situation could be quite different: ‘There are usually no large open spaces there. But, for example, you can easily use the roofing of a car park or reinforce the roofs of shopping centres and industrial plants. That is why we are also testing new lightweight photovoltaic systems for our campus,’ explains Andreas Gerber.

Dr Andreas Gerber from the Institute of Energy Materials and Devices (IMD-3 Photovoltaics), LLEC team manager for the field of photovoltaics. Photo: Forschungszentrum Jülich/Kreklau

Schools laboratory as a pioneer

One building that has already been converted on the Jülich campus is the JuLab Schools Laboratory. Its roof terrace is equipped with a photovoltaic pergola made of semi-transparent modules and a photovoltaic roof system. And right next to it, the rotor of a small wind turbine is turning. ‘Here we have built a small-scale LLEC. Components of the system can be tested in advance before the technologies are implemented on a larger scale on campus,’ explains Stefan Kasselmann. For example, the conference rooms are equipped with special sensors: they detect, for example, how many people are in the room. “Body heat alone slowly heats up a room,” says Stefan Kasselmann, ’so the heating is automatically turned down accordingly. This saves heating energy without being noticed.’

The sensors not only measure the temperature of the room and the heating, but also data such as the carbon dioxide concentration, humidity, brightness and the opening state of doors and windows – not only in JuLab, but also in many other rooms of the LLEC. Information about the weather is also included. The data is processed by the ‘brain’ of the LLEC. The cloud-based information and communication technology (ICT) with its control software ensures the correct balance of energy flows between the nodes of the network.

A unique demonstrator

Sun and wind do not always provide the same amount of energy. ‘If more electricity is generated than needed, we have to store it – for the bad times, so to speak. To do this, we are setting up various storage options at the LLEC,’ explains Stefan Kasselmann. ‘We can store energy in two large batteries or hydrogen in chemically bound form. The hydrogen storage system can be used to bridge dark, windless periods of days or even weeks.’

The hydrogen is obtained from water using electrolysis cells. It can then be stored. As part of the LLEC project, this is done by chemically binding the hydrogen molecules to a carrier liquid, releasing heat. The waste heat from the hydrogenation is used by the energy centre in the research centre, thus reducing the heat production of the energy centre. The carrier liquid is a so-called liquid organic hydrogen carrier (LOHC). A unique demonstrator is currently being developed in Jülich for this purpose.

Visualisation of the planned LOHC plant at the central heat supply of the Jülich Research Centre. Source: Forschungszentrum Jülich GmbH | .mattomedia KG

The company Hydrogenious LOHC Technologies GmbH, which is also a partner in the demonstration project Multi-SOFC at the hospital in Erkelenz, has manufactured the reactor required for this. It is currently being installed on the Jülich campus. A pipeline is also being planned to transport the oxygen and hydrogen produced by the electrolyser to the energy centre. The entire system is scheduled to be put into operation next year.

In the future, the new infrastructure will ensure that the hydrogen produced with the help of surplus electricity is stabilised so that it can be converted back into electricity when there is not enough sun or wind. The hydrogen can be released from the carrier liquid LOHC as needed using heat from the energy centre. Similar to the principle of deposit bottles, the liquid can be reused afterwards. According to a study by Forschungszentrum, the loading and unloading cycle can be repeated more than 200 times.

Central role for sector coupling

The hydrogen can also be converted back into electricity using a fuel cell. ‘But we could also burn it – and thus replace some of the natural gas that will be used by the energy centre built on campus to generate electricity, heating and cooling. Hydrogen will therefore play a central role in sector coupling,’ says Dr. Holger Janßen, head of the Stacks and Systems (Electrolysis) group at the Institute of Energy Technologies (IET-4 Electronic Process Engineering). The role this will play in which application and how hydrogen and battery storage, for example, complement each other in a meaningful way – this is what Forschungszentrum Jülich is investigating in a kind of self-experiment with the LLEC. ‘That’s the advantage of a real-world laboratory: we identify new challenges in the interaction between science, technology and society that we would not have thought of without direct practical relevance,’ says Stefan Kasselmann.

Dr Holger Janßen, group leader for stacks and systems, Institute of Energy Technologies (IET-4). Photo: Forschungszentrum Jülich/Kreklau