Emission-free combustion

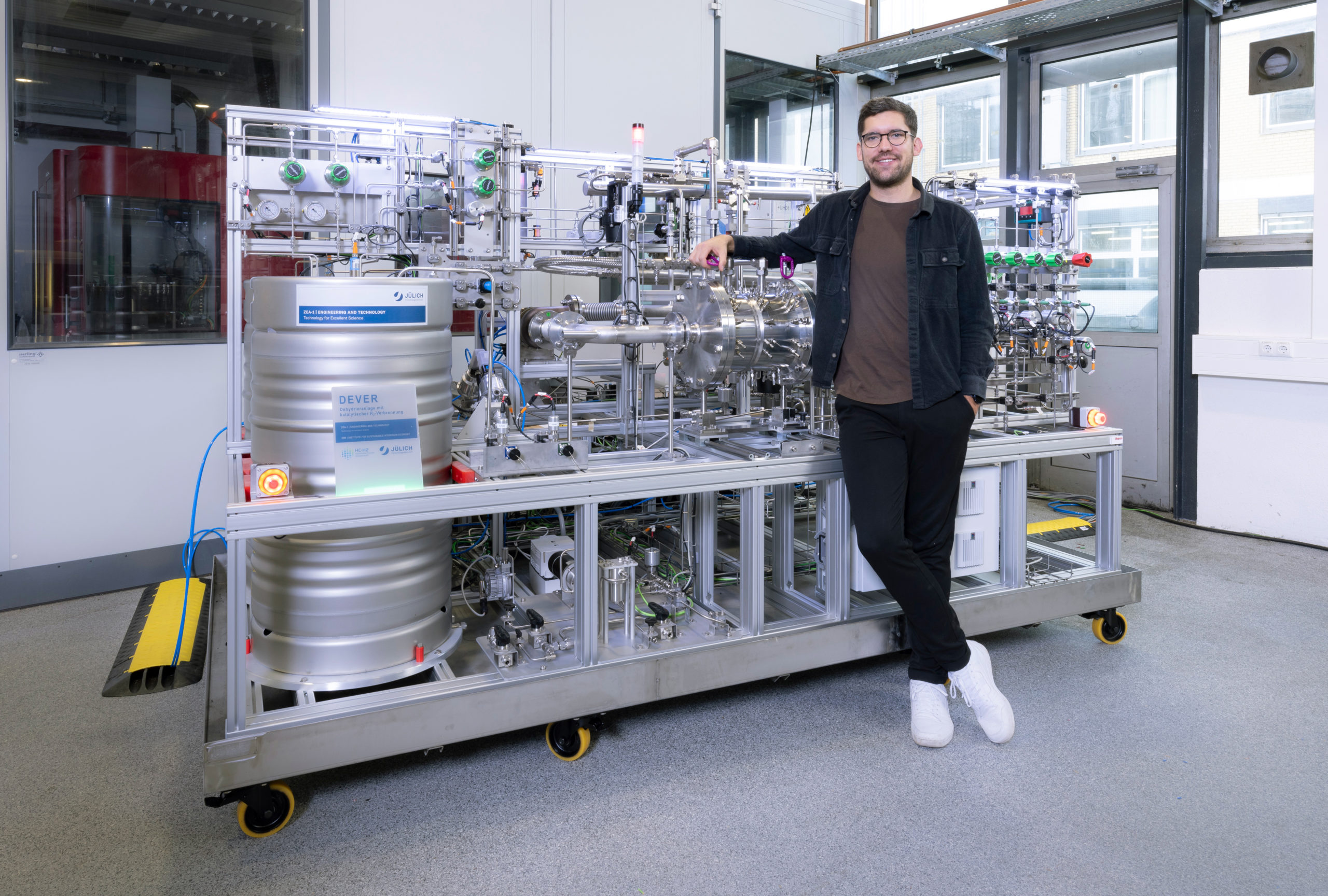

‘Catalytic combustion starts at ambient temperature and allows the user to select a desired temperature. This means that no NOX emissions are produced,’ says Simon Hahn. This is an advantage that conventional heat generation with the hydrogen flame does not have. Photo: Forschungszentrum Jülich/Nörig

What can hydrogen do? When Jülich chemical engineer Simon Hahn answers this question, he not only talks about its potential as an energy store. His idea for founding a company is based on the property that hydrogen can produce a desired temperature of up to 500 degrees without causing emissions by means of so-called catalytic combustion.

The system that Simon Hahn has developed is called DeVer. DeVer stands for dehydrogenation and combustion. Dehydrogenation refers to the release of hydrogen atoms from a larger molecule. ‘To be more precise, DeVer stands for dehydrogenation coupled with catalytic combustion,’ explains Simon Hahn, who is still conducting research at the Institute for Sustainable Hydrogen Economy (INW) at the Forschungszentrum, but will soon be setting up his company in the Startup Village Jülich in the neighbourhood.

Simon Hahn is setting up his own business with his idea of catalytic hydrogen combustion. Photo: Forschungszentrum Jülich/Jansen

The business idea is to burn hydrogen catalytically and thus generate heat for various applications in a targeted manner. ‘Catalytic combustion is safe, efficient and completely emission-free. So not only free of carbon dioxide. There are also no nitrogen oxides as in the case of hydrogen combustion in the flame,’ explains the prospective founder. One possible application is the so-called LOHC deposit bottle. LOHC are carrier fluids that can store hydrogen atoms in their molecules. A temperature level of almost 300 degrees is necessary for dehydrogenation. DeVer can provide this. ‘The big advantage is that the release and catalytic combustion can take place in one reactor. This saves space and is more efficient.’

Reaction at a catalyst

‘Catalytic combustion starts at ambient temperature and allows the user to select a desired temperature,’ says the chemical engineer. This is an advantage that conventional heat generation with hydrogen does not have. Conventional means that the hydrogen is combusted like natural gas or oil with the help of a flame. Catalytic combustion takes place without a flame. Hydrogen and oxygen react together on a catalyst. This produces water vapour and heat. And this heat can be used, for example, for many industrial applications. ‘Whether it’s food, clothing, paper, steel, plastic… Almost everything we use every day has been heated at some point to make it durable, edible or malleable, or to dry it,’ says Simon Hahn, outlining potential applications. ’The high temperatures required in industrial processes cannot be achieved with heat pumps. And that’s where hydrogen comes in.’

The laboratory setup is now being followed by the demo version. The Central Institute of Engineering, Electronics and Analytics (ZEA-1) at the Forschungszentrum has built the demo-DeVer according to Simon Hahn’s plans. More will follow. The budding entrepreneur plans to adapt them in terms of design and dimension to the needs of future customers.

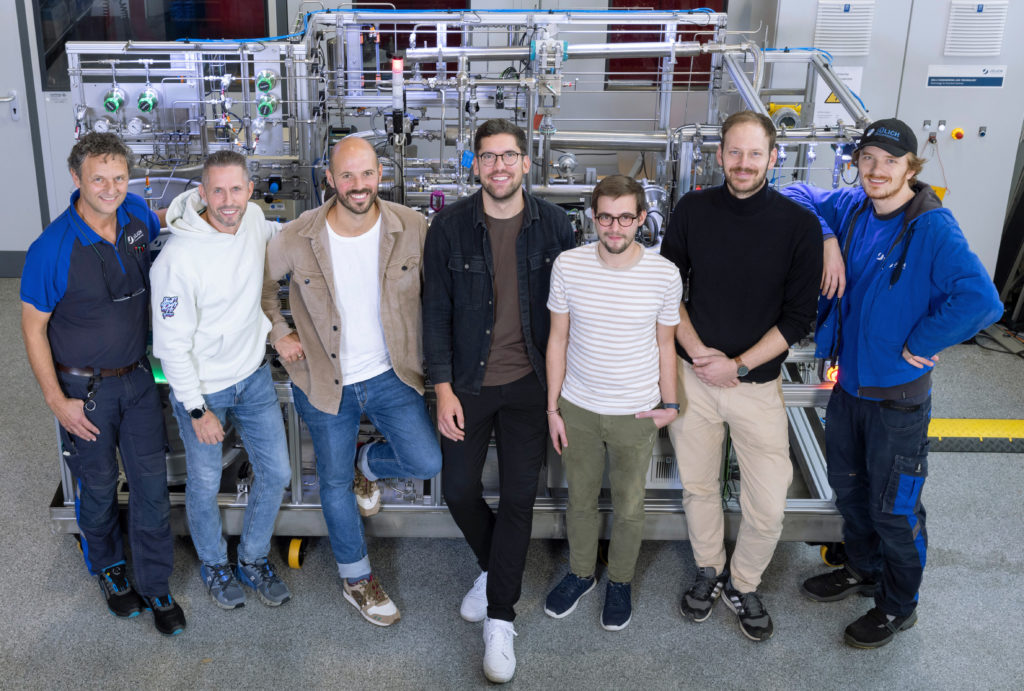

Proud of the construction of the first demonstration-scale plant: chemical engineer Simon Hahn (centre), Sebastian Thill (team leader at the Institute for Sustainable Hydrogen Economy at Forschungszentrum Jülich, 2nd from right) and the team from the Central Institute for Engineering, Electronics and Analytics (ZEA-1) at Forschungszentrum Jülich, which built the plant. Photo: Forschungszentrum Jülich/Nörig