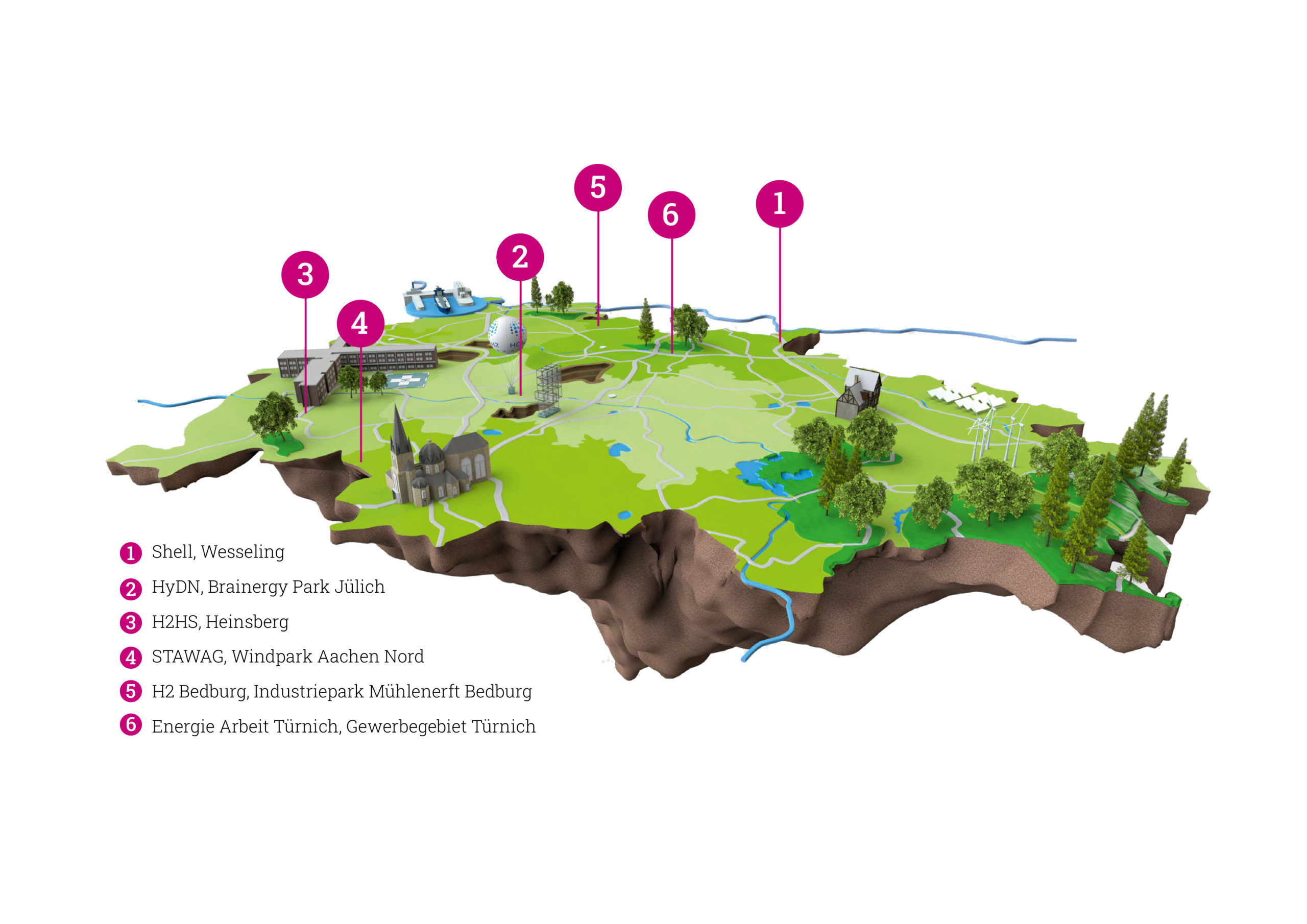

Who has the largest electrolyser? The race is obviously on. And that’s a good thing. Because it indicates that the forecasts of Prof. Peter Wasserscheid in his interview are correct. The construction of new electrolysers for the production of green hydrogen in Germany is clearly picking up speed. This is particularly evident here in the Rhenish mining area. On these two pages, we provide an overview that does not claim to be complete.

In 2023, the German government’s new hydrogen strategy set a target of 10,000 megawatts (MW) for 2030. According to the page www.wasserstoff-kompass.de, electrolysis capacity in Germany was 154 MW at the mid-year point, so it was still a long way from the target. Nevertheless, the expansion is now gathering pace. RWE has announced that it will start operations with a 100 MW electrolysis plant in Lingen, Lower Saxony, next year, which is to be expanded to 300 MW by 2027.

Where will green hydrogen come from in the future?

On the one hand, as imports from countries that can produce it in larger quantities and at a lower cost. In addition to storage and transport over long distances, this is one of the key topics of our Institute for a sustainable hydrogen economy at Forschungszentrum Jülich. And, of course, from the many larger and smaller production plants in Germany that are emerging and will soon ensure that green hydrogen works in exactly the same way as the other pillars of the energy system of the future: decentralised and independent of a few countries that currently profit from fossil fuels.

There is visible growth in the Rhineland. A major project has the name REFHYNE II. From 2027, the 100-megawatt PEM electrolyser is to produce up to 44 tonnes of hydrogen per day at the Shell Energy and Chemicals Park Rhineland in Wesseling. PEM stands for: Proton Exchange Membrane (proton exchange membrane). REFHYNE II is based on the knowledge gained by the group from the 10 MW electrolyser at the same location, which has been in operation since 2021.

A comparison that shows there is still a long way to go: Thyssenkrupp, the operator of the hydrogen-based steel production tkH2Steel in Duisburg, has announced that it will require around 380 tonnes of hydrogen per day when in full operation from 2029. Around 2.3 million tonnes of liquid pig iron are to be produced in this way each year. According to the German Steel Federation, this corresponds to around ten percent of current production in Germany.

Hydrogen for trains and buses

HyDN GmbH‘s 10 MW electrolyser is due to start up next year in Jülich. Right in Brainergy Park Jülich, which is also home to the Helmholtz hydrogen cluster. HyDN is a joint venture between the district of Düren and Messer Industriegase. The aim of the electrolysis there is to supply the regional railway line and the bus fleet with hydrogen. Messer intends to sell the surplus hydrogen. ‘We want to show that it is possible to produce green hydrogen locally for regional use,’ says Wolfgang Spelthahn, District Administrator of Düren. “It is quite conceivable that we will scale up the plant soon after its launch. The modular design also allows for 30 MW or more.” The electrolysis plant is supplied with energy from the adjacent photovoltaic fields and nearby wind turbines.

Hydrogen for local bus transport: this is also the direction in which H2HS, a consortium of five companies from the Heinsberg district, including NEUMAN & ESSER from Übach-Palenberg, Frauenrath from Heinsberg, BMR Energie Solutions from Geilenkirchen, Veolia from Heinsberg and WEP from Hückelhoven, is heading. From the beginning of 2025, the plant is to produce around 70 tonnes of green hydrogen annually to supply twelve hydrogen buses with a newly established filling station. H2HS states that the maximum total production capacity will be around 200 tonnes per year. The necessary energy comes from wind turbines in the cities of Heinsberg, Hückelhoven and Geilenkirchen.

Heavy goods traffic in view

Wind turbines will also be used to power the electrolysis plant that the Aachen-based utility STAWAG is building. Here, too, the focus is on green hydrogen that is produced and used regionally. The energy comes from the Aachen Nord wind farm. It is conceivable that the hydrogen will be made available locally for public transport or heavy goods traffic, or sold to other consumers.

A 5 MW electrolysis plant is currently being built in the Mühlenerft industrial park in Bedburg and is scheduled to go into operation at the end of 2026. The project, called H2 Bedburg, involves connecting the electrolyser to a filling station for industrial and private use, as well as to a hydrogen filling station. The project is designed to be modular and can be scaled up to 15 MW later if required.

The Energie Arbeit Türnich project in Kerpen will achieve 15 MW at the first go when it is completed. The city of Kerpen is working together with the municipal utilities of Kerpen, the Jülich Research Centre, Siemens Energy and Westenergie. The plan is to have an electrolysis capacity of around 20 MW, which will be used to supply local public transport and the hydrogen-powered trucks of local logistics companies. Large pressure tanks will ensure that hydrogen is available at all times, despite fluctuations in the renewable energy supply. A filling station will also be used to distribute hydrogen to customers by trailer.

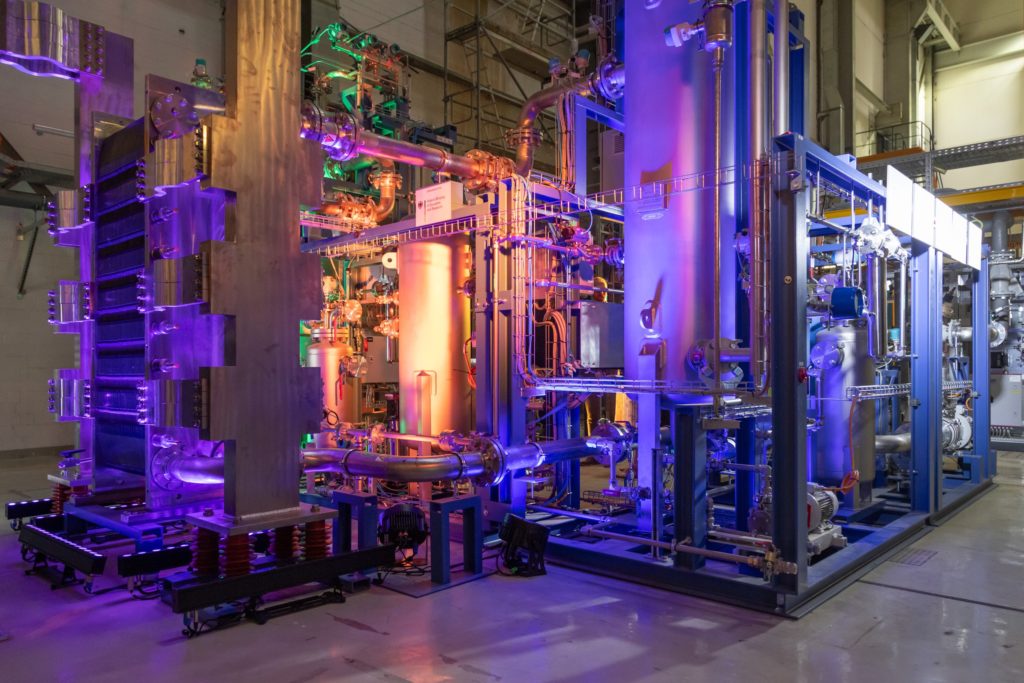

The DERIEL test stand

Since the summer, Forschungszentrum Jülich (FZJ) has been operating a state-of-the-art test stand for industrial-scale electrolysers. The plant of the DERIEL project (DE–RIsking PEM electrolyser), which is coordinated by Siemens Energy, is part of the hydrogen lighthouse project H2Giga of the Federal Ministry of Education and Research (BMBF). It should help to make electrolysers ‘made in Germany’ even more efficient and durable. The BMBF is funding the project with around 100 million euros.

‘With the inauguration of our PEM electrolysis test facility from the DERIEL project, we want to provide important impetus for the hydrogen economy in Germany,’ says Prof. Peter Jansens, member of the Board of Directors of Forschungszentrum Jülich responsible for energy. ’Our research, from materials research to market readiness, not only strengthens Germany’s technological competitiveness but also drives the application of innovative technologies.’

Extending the lifespan of electrolysers

The DERIEL test facility in Jülich is designed for industrial-scale electrolysers and is equipped with the latest sensor technology. The partners want to use the test stand to examine and optimise numerous parameters that are crucial for the costs and lifespan of electrolysers. ‘Germany wants to become a leading provider of hydrogen technologies,’ explained Till Mansmann, the BMBF’s innovation officer for ‘green hydrogen’, at the inauguration of the test facility.

‘To achieve this, electrolysers made in Germany must be more efficient and durable than those of the competition. This is exactly what we are currently making possible at Forschungszentrum Jülich.’ The DERIEL project aims to better understand the ageing of electrolytic cells by using dozens of sensors at all levels, with cameras and complex measurement technology. The findings will then be incorporated into future generations of electrolysers.

‘With our research and development of water electrolysis on a megawatt scale, we are setting new global standards in the cooperation between science and industry,’ says Prof. Rüdiger A. Eichel from Forschungszentrum Jülich, who is in charge of the project.